PowerVac® P Vacuum System Operation Troubleshooting

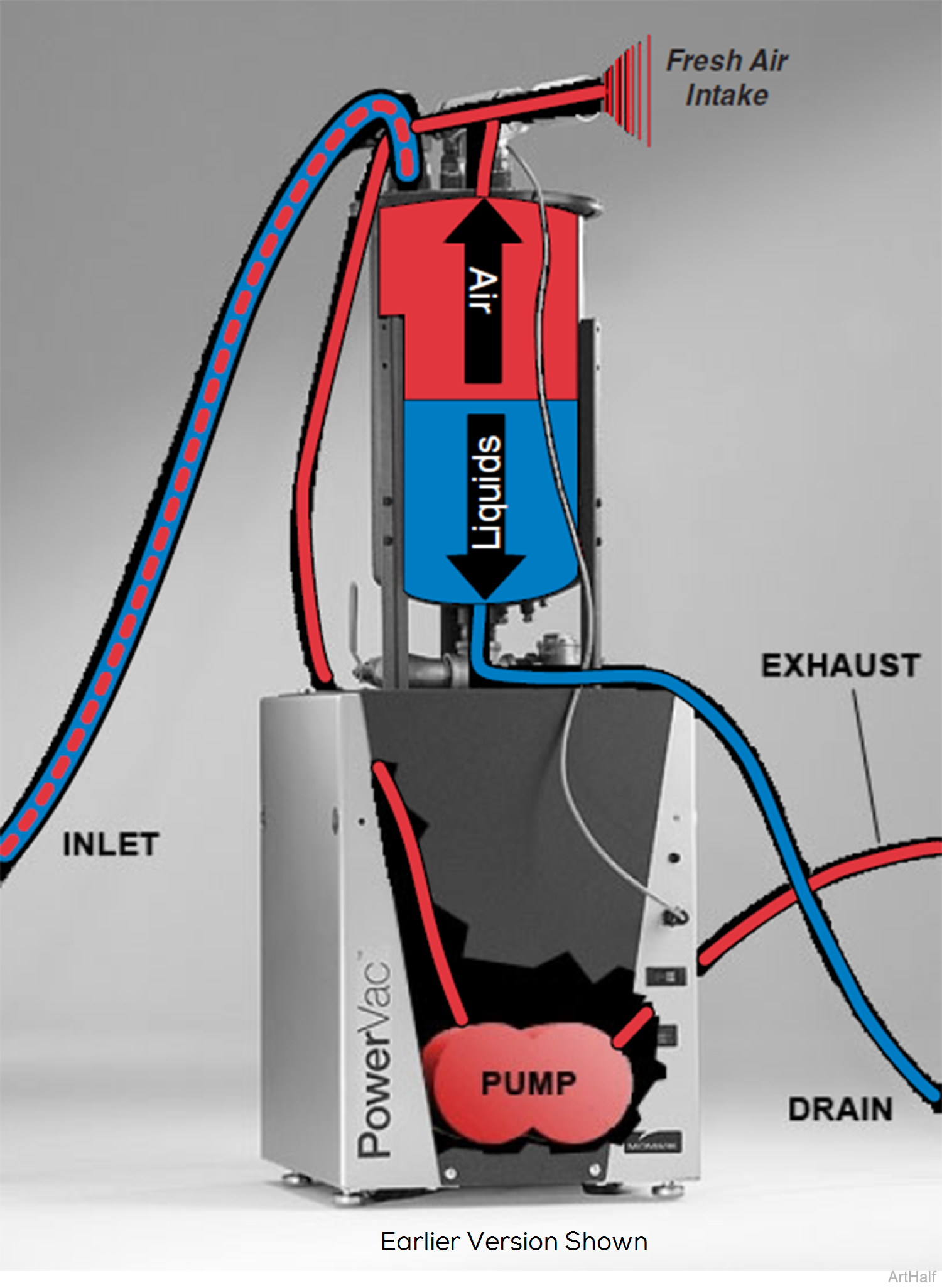

Operatory waste (air, solids and liquids) is pulled into the separator through the inlet hose by the rotary claw pump in the vacuum base unit.

Air is separated from liquids and solids. Air then flows into the pump and out through the exhaust hose.

Fresh air is pumped in through the Vacuum Relief Valve to the pump and out through the exhaust. When ports are opened in the operatories, the VRV closes to compensate.

The check valve connected below the drain port allows the unit to drain liquids and solids upon removal of vacuum from the chamber when the pump / motor shuts off.

The fan(s), hour meter and vacuum pump start to run when power is supplied by the wall switch. The fan(s) and hour meter then begin to cycle with the vacuum pump / motor. The float switches control the pump motor by a 24 vac relay via motor contactor.

The upper and lower reed switch floats interact as a latching circuit with the internal relay to release upon drain below the bottom float.