PowerVac® P Pump Test and Repair

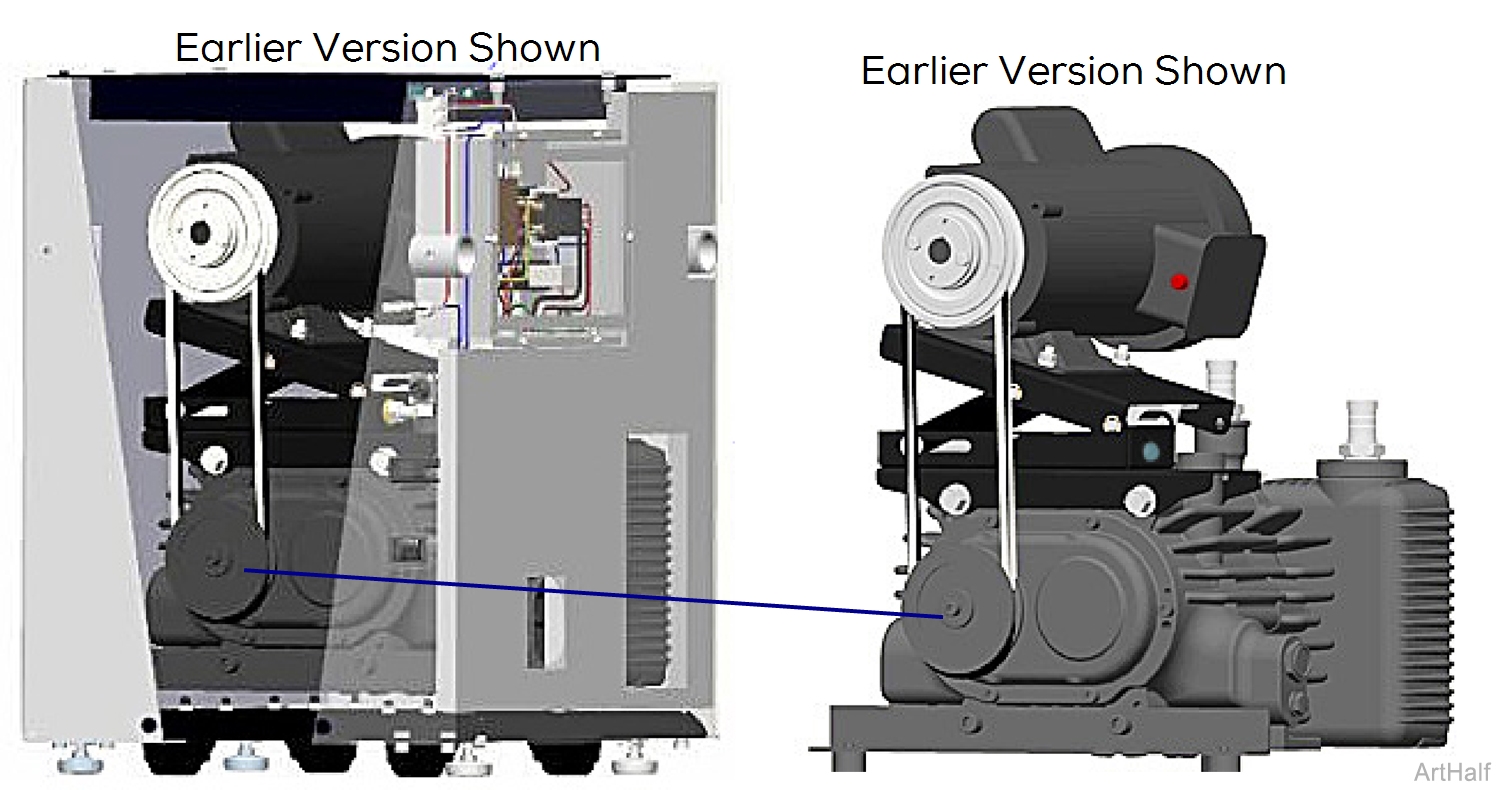

The "dry" vacuum pump requires no lubricant in the pumping chamber. The pump is a dual rotary claw type, belt driven by a 2 HP single phase, 208-230 volt motor.

1.Disconnect power at on/off switch and main power supply box.

2.Check pulley to see if it's locked up. Use belt to check pulley. Try to work pulley loose, turn with hand.

If pulley does not move, continue with Steps 3, 4 and 5.

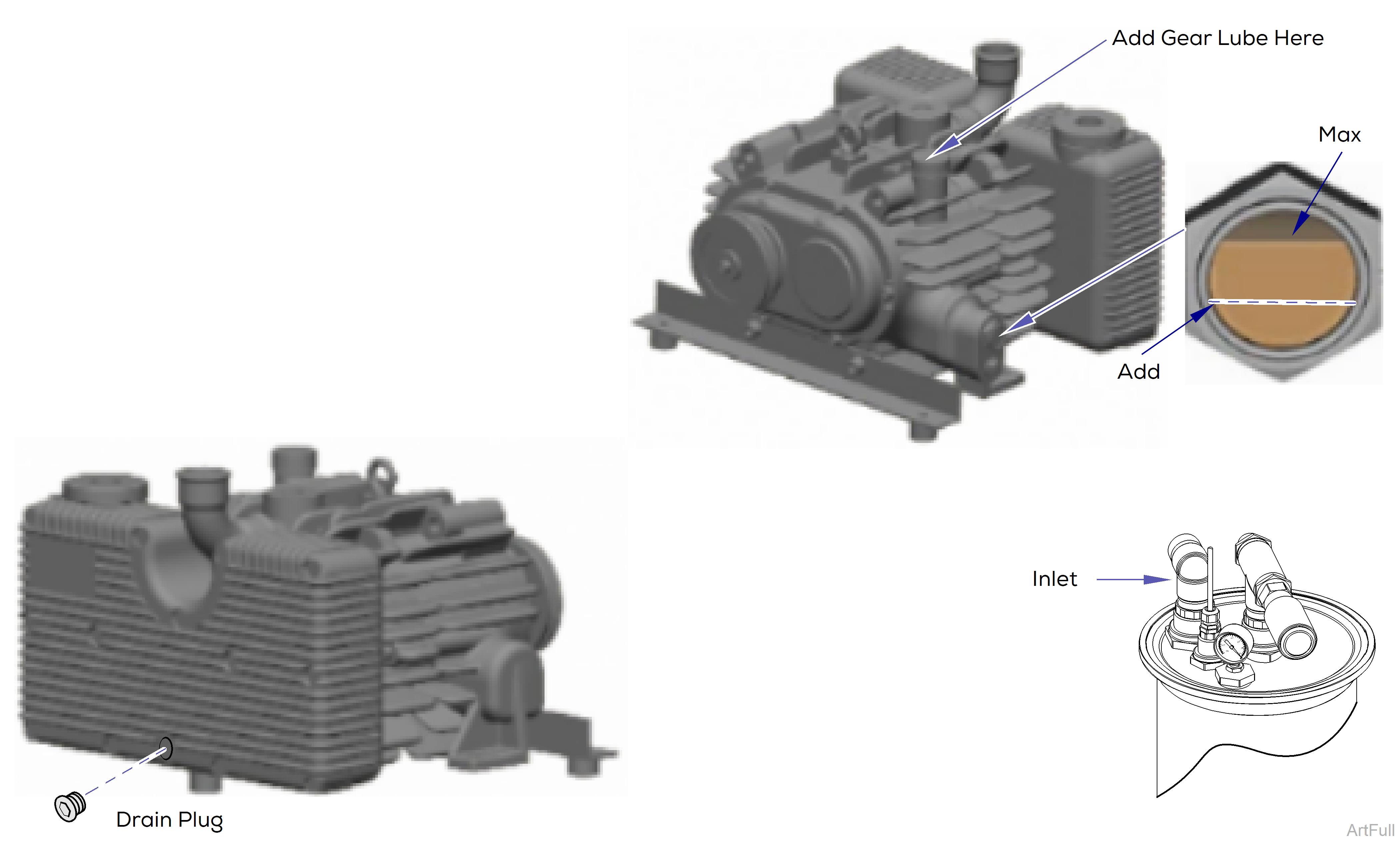

3.Check gear lubricant level. Add if below 1/3 full. Use only Midmark gear lube P/N 064-0028-01. Remove inlet hose to add gear lube.

If gear lube is not light yellow /clear opaque color, it will need to be changed. Refer to: Pump Change Gear Lube section below.

4.To drain pump check for water in pump.

a.Remove drain bolt off pump and barb fitting at the bottom of the exhaust p-trap to release any water inside.

b.When pump and p-trap are done draining replace drain bolt and barb fitting.

Water may flood out, set funnel under bolt hole to move water from pump into a bucket or tray.

5.After draining pump you must:

a.Remove inlet hose either at pump or at separator.

b.Pour 2 ounces (1/4 cup) of conditioning fluid (002-1910-02), or WD-40 if unavailable, into pump and let soak.

c.Try to work pulley loose as fluid migrates through pump.

d.If pump will not free up order Timer/Conditioning Fluid Kit (002-1910-01) and Socket kit (002-1911-00)

e.If pump rotates freely restore power and start vacuum. Order Timer/Conditioning Fluid Kit (002-1910-01) if needed.

The PowerVac® gear lube should be changed every 10 years. It will take approximately 2/3 of a quart of Midmark PN 064-0028 which can be ordered in a quart or a liter.

1.Run PowerVac for 5-10 minutes. Disconnect main power supply to the PowerVac.

2.Remove front cover. Refer to: Front Cover

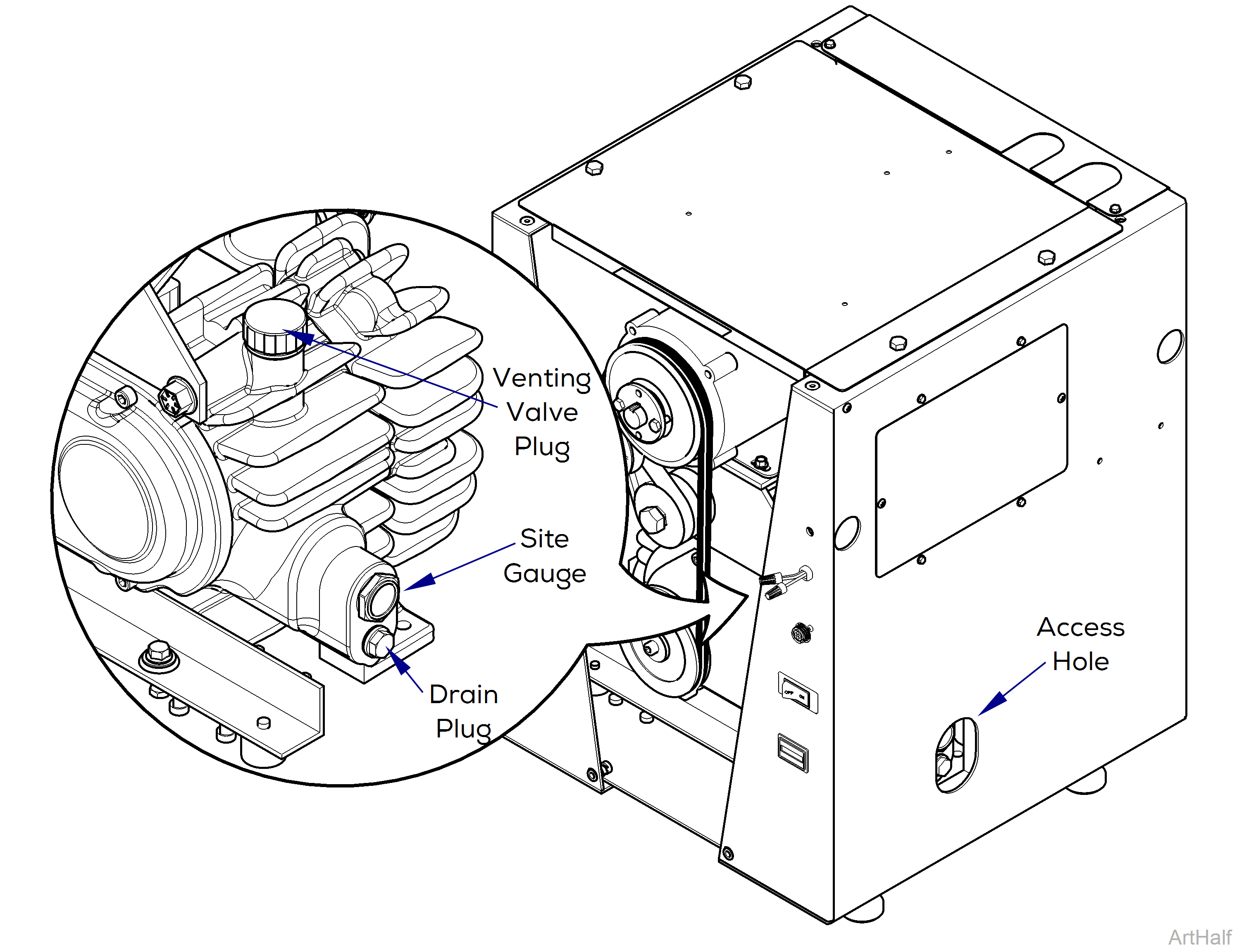

3.Remove venting valve plug.

4.Siphon gear lube out from venting valve hole.

If you do not have a siphon hose, you may access the drain plug located below the site gauge. Place an oil absorbent mat under drain hole and funnel the gear lube out the side access hole in housing into a drain tray.

5.Fill in new gear lube until the level is slightly above the middle of the site gauge. Verify seal ring on vent valve is undamaged. Replace vent valve plug and or drain plug. Clean any gear lube that leaked on inside or outside housing.

Dispose of gear lube in compliance with applicable regulations.

6.Replace front cover. Connect main power supply. Run pump for 5 minutes and recheck the gear lube on the site gauge.