Midmark® Smart G-Vacuum System Theory of Operation

The demister and filter are meant to reduce the amount of harmful liquids and solids from entering the pump.

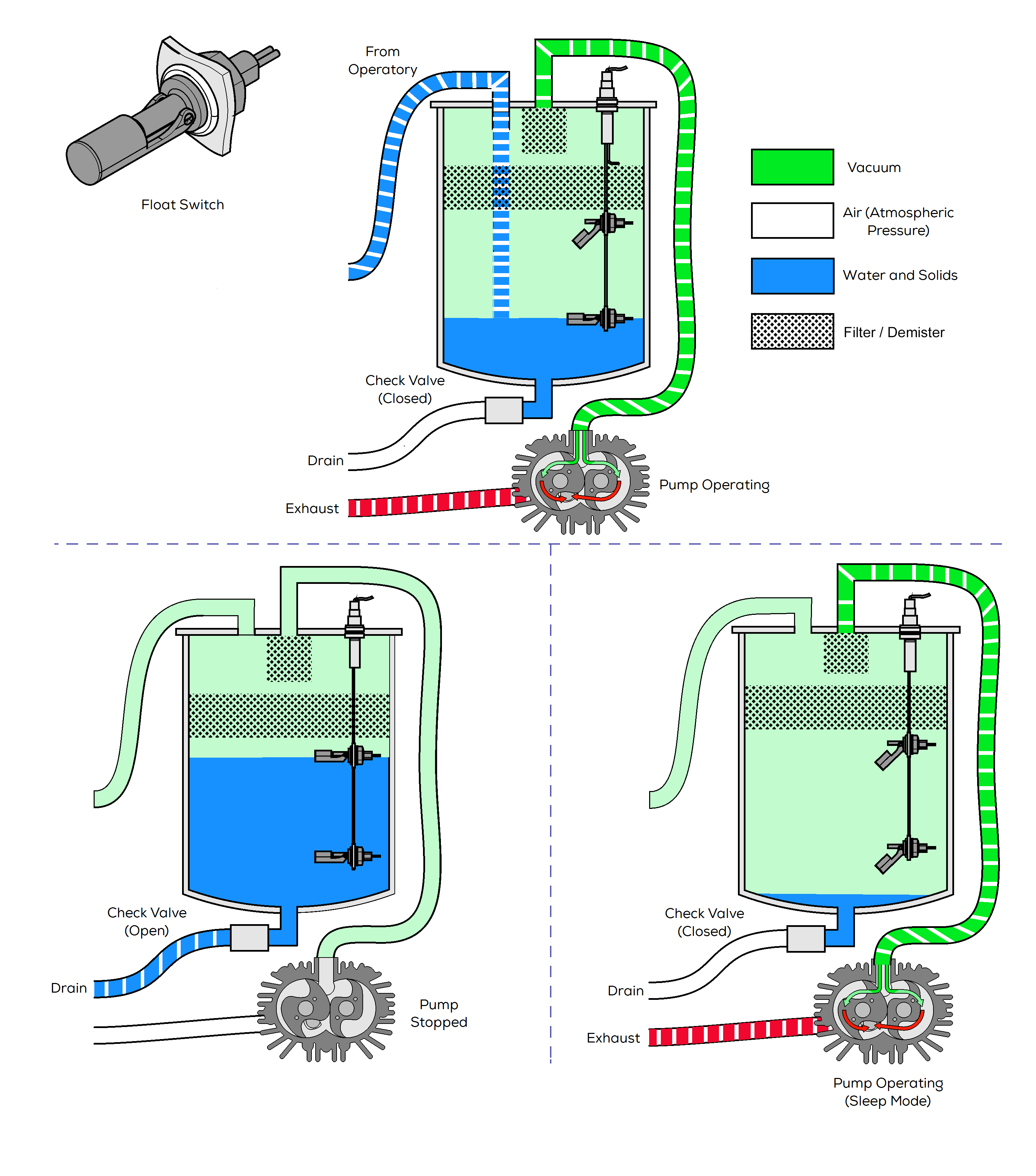

Air, water and solids from the operatory are pulled into the separator. Air is expelled out through the pump exhaust while water and solids fall to the bottom of the tank. The vacuum in the separator keeps the check valve to the drain closed and the tank gradually fills.

The rising fluid level eventually closes the top float switch, which turns the pump off. Since vacuum is no longer being maintained, the check valve opens allowing water and solids to drain from the separator. The upper and lower reed switch floats interact as a latching circuit with the internal relay to release upon drain below the bottom float.

If the power is shut off, the unit will drain automatically due to a loss of vacuum regardless of the water level in the tank.

When the tank drains enough to open the bottom float switch, the pump starts running again. This restores vacuum and closes the check valve.

If the power is turned off, tank will drain completely.

When no instruments (suction tips) are being used (HVEs shut off for 5 seconds or more) the system goes into sleep mode to save energy. Sleep mode pressure is set to 6”Hg. Vacuum pressure will ramp down from its normal operating pressure to sleep mode pressure when the unit goes to sleep. The sleep mode pressure is maintained at 6”Hg until the variable frequency drive (VFD) senses an increase in vacuum pressure is required when an instrument (suction tip) has been opened. The VFD will then speed up the motor to increase vacuum pressure to the normal operating pressure.