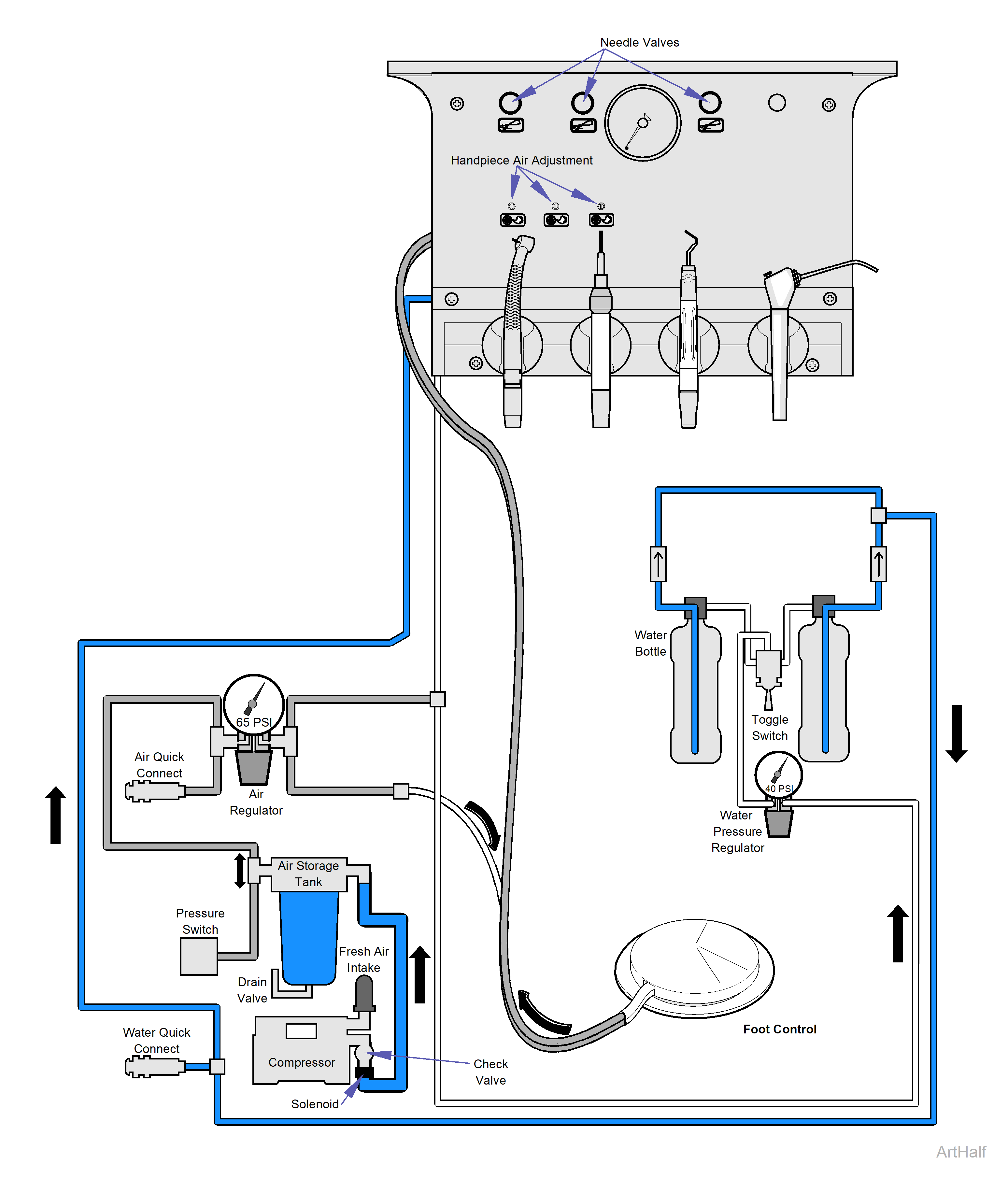

Midmark® 1000 Compression Cycle and Air Flow Theory of Operation

Atmospheric air is drawn in through the intake filter to the compressor head where air is compressed and exhausted. Air travels though the check valve, which prevents air flushing back into the head, then flows through the solenoid. The solenoid allows air to escape for approximately two seconds during start-up to relieve pressure from the head, then closes sending pressurized air to the storage tank. Air from the storage tank activates the pressure switch. As the storage tank fills the pressure switch opens at a preset pressure and stops the compressor.

The air regulator adjusts air from the storage tank to 65 PSI. Storage tank air also supplies the quick disconnect. Air going to the quick disconnect is not regulated and pressure is at 100 PSI. Accessories connected to the quick disconnect will need to have it’s own regulator installed if the manufacture recommends less than 100 PSI.

The regulated air (65 PSI) flows to the foot control and water bottles. When user activates the throttle valve by depressing the foot control, air is sent through the tri-block and each instrument manifold. When the instrument is removed from the holder the holder valve is activated allowing air to flow through the handpiece. There are drive air adjustment valves to adjust air pressure for the instruments.

The air/water syringe is activated by pressing on the instrument’s air and water buttons. The user can make drive air, coolant air and water flow adjustments. Air flows though the gauge to show pressure readings. Regulated air also pressurizes the water bottles. Air to the water bottles is adjusted to 40 PSI by the water pressure regulator and can be lowered by adjusting the water pressure regulator.