355 Light Lighthead Test and Repair

Screws securing lamp tube / lighthead must be installed properly. Failure to do so may allow lighthead to fall, resulting in injury.

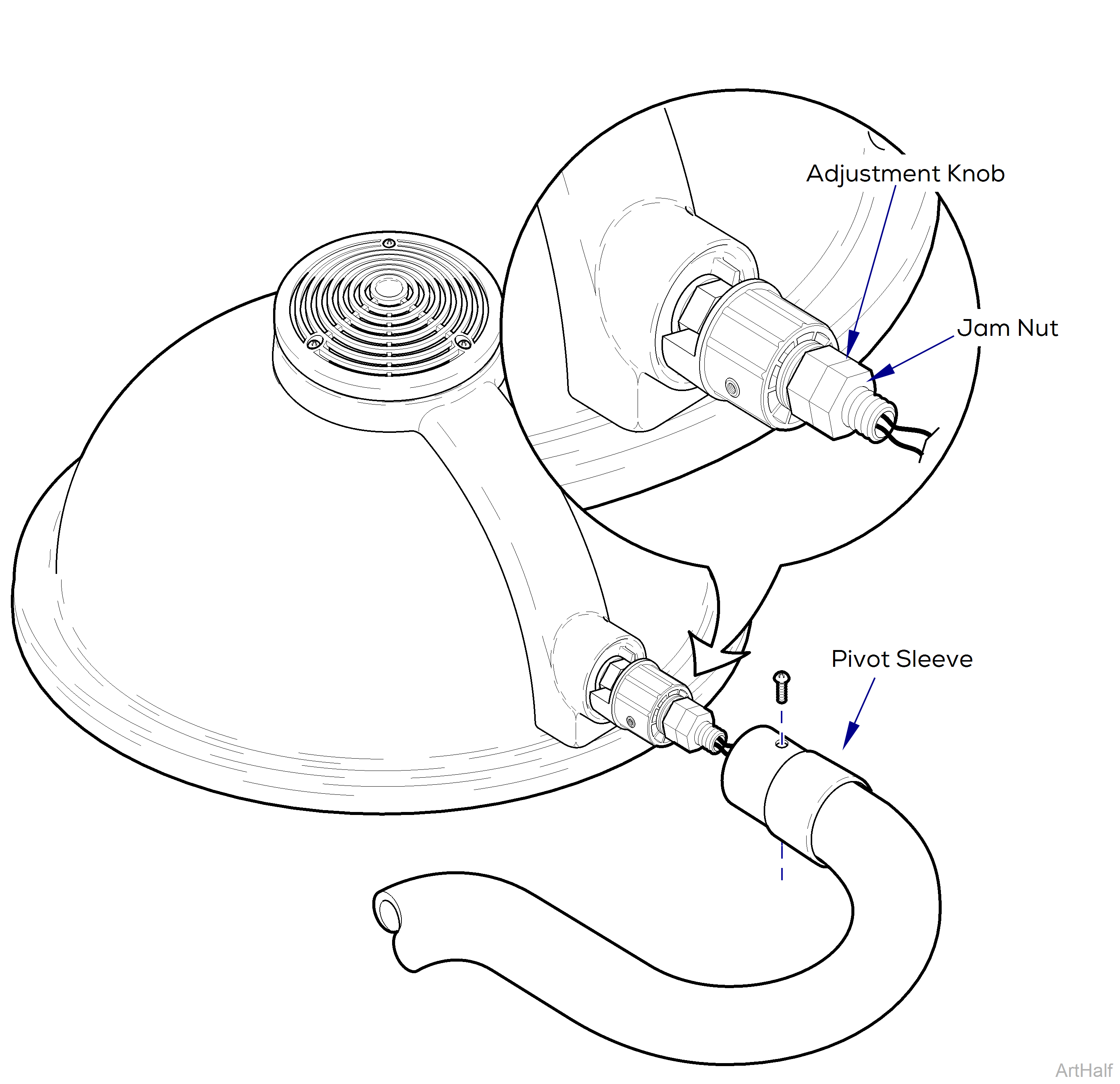

To Adjust Lighthead Brake Tension

1.Slide pivot sleeve back, then remove two screws.

2.Separate lamp tube from lighthead.

3.Loosen jam nut.

4.Loosen / tighten adjustment nut as necessary.

5.Hold adjustment nut in place, then tighten jam nut to 20-30 ft-lbs (27-40.7 N•m).

6.Reattach lamp tube / lighthead, secure with two screws.

7.Check for proper operation. Repeat if necessary.

To prevent risk of shock always disconnect power before removing covers or performing any service procedure.

1.Disconnect power to light.

2.Slide pivot sleeve back, then remove two screws.

3.Separate lamp tube from lighthead, disconnect two wires.

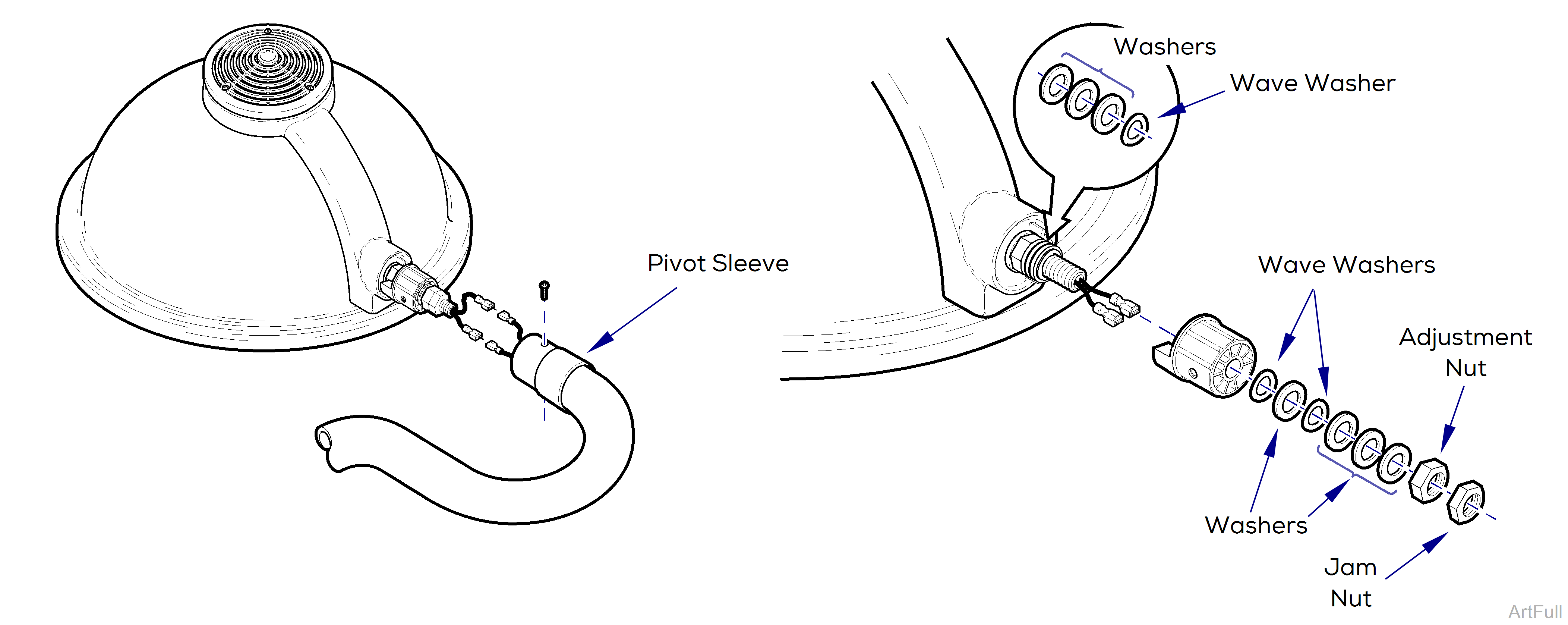

4.Remove two nuts, washers, and pivot bearing.

Screws securing lamp tube / lighthead must installed properly. Failure to do so may allow lighthead to fall, resulting in injury.

1.Install pivot bearing and washers as shown in illustration.

2.Install two nuts, but do not tighten at this time.

3.Loosen / tighten adjustment nut as necessary.

4.Hold adjustment nut in place, then tighten jam nut to 20-30 ft-lbs (27-40.7 N•m).

5.Connect two wires.

6.Reattach lamp tube / lighthead, secure with two screws.

7.Check for proper operation. If necessary, separate lighthead, and loosen / tighten adjustment nut.