355 Light Ball Pivot Bearing Test and Repair

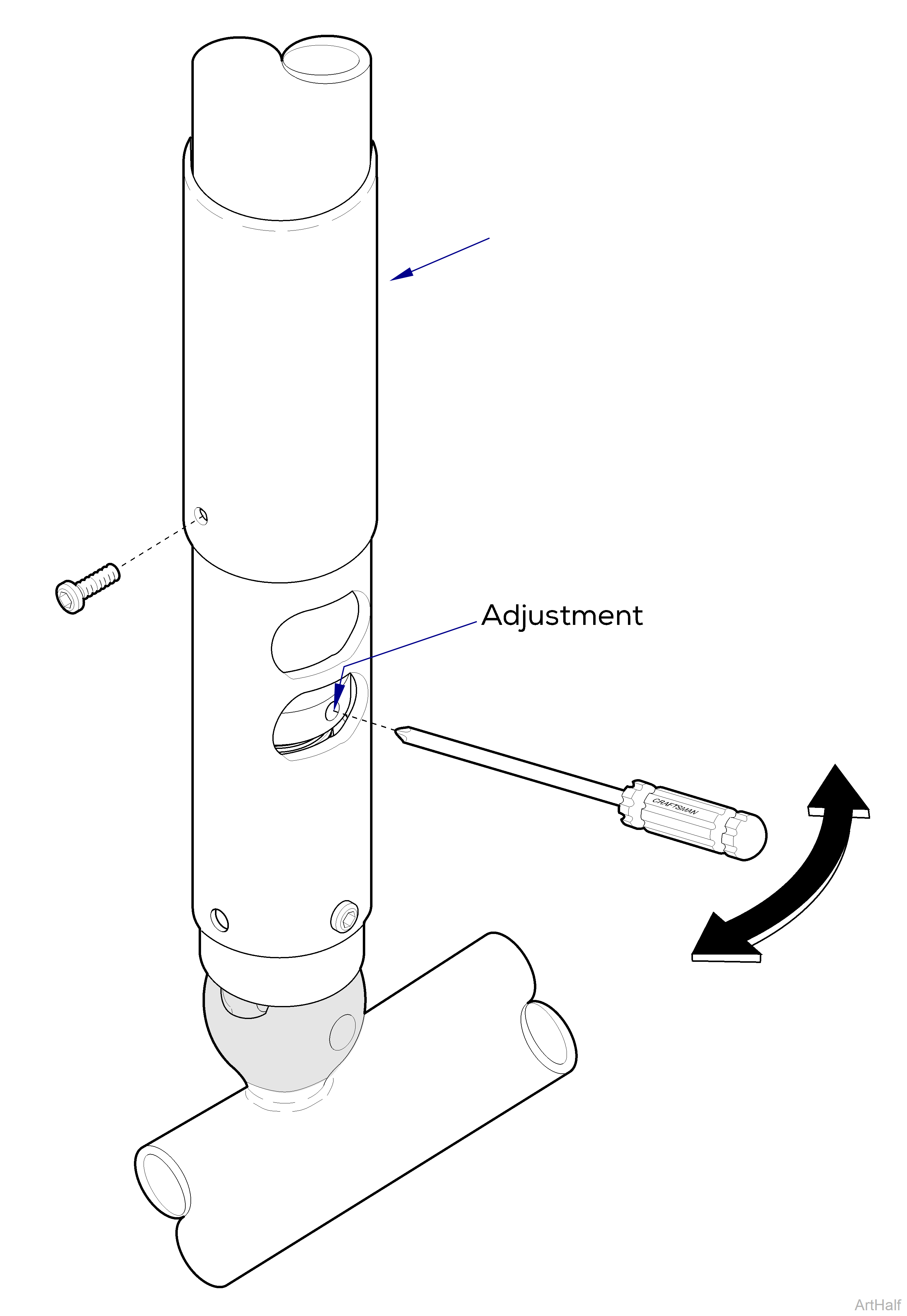

1.Slide sleeve up to expose opening.

2.Insert screwdriver into adjustment hole.

3.Move the screwdriver left until tension is fully released.

1.Insert screwdriver into adjustment hole.

2.Move the screwdriver left / right to adjust tension setting. Left decreases tension. Right increases tension.

3.Remove screwdriver and check for desired tension. Repeat until desired tension is achieved.

4.Slide sleeve down, then install screw.

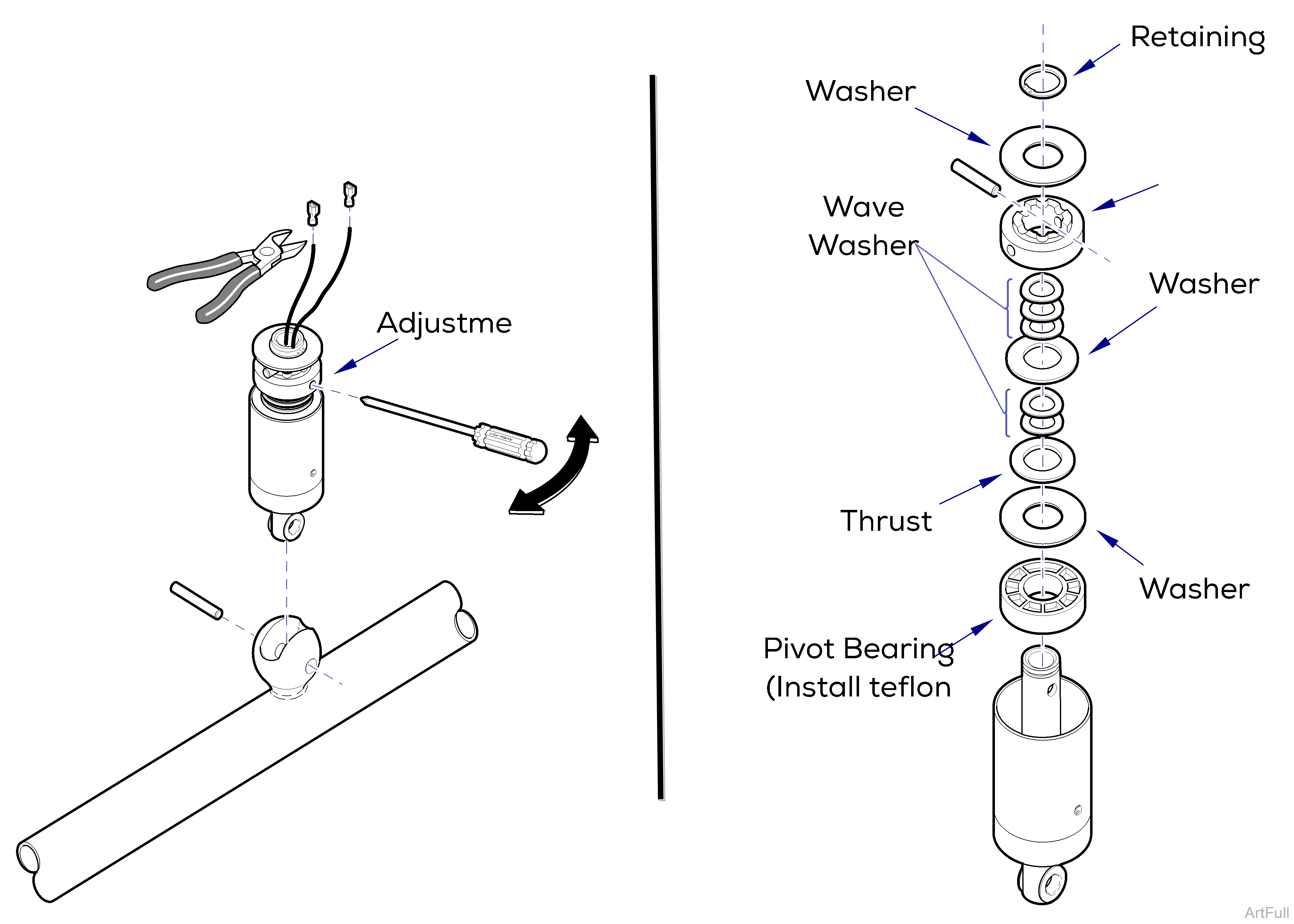

1.Insert screwdriver into adjustment hole.

2.Move the screwdriver left until tension is fully released.

3.Cut wire connectors from two wires. Preserve as much wire length as possible.

4.Using a punch, remove groove pin.

1.Remove retaining ring and washer from ball pivot shaft.

Groove pin has serrations on one end. Do not drive serrations thru ball pivot shaft.

2.Using a punch, remove groove pin.

3.Disassemble ball pivot components from shaft / housing.

4.Inspect pivot bearing for excessive wear. Replace if necessary.

1.Install pivot bearing, washers, and cam as shown.

2.Install groove pin.

3.Install washer, then secure with retaining ring.

Groove pin has serrations on one end. Do not drive serrations thru ball pivot shaft.

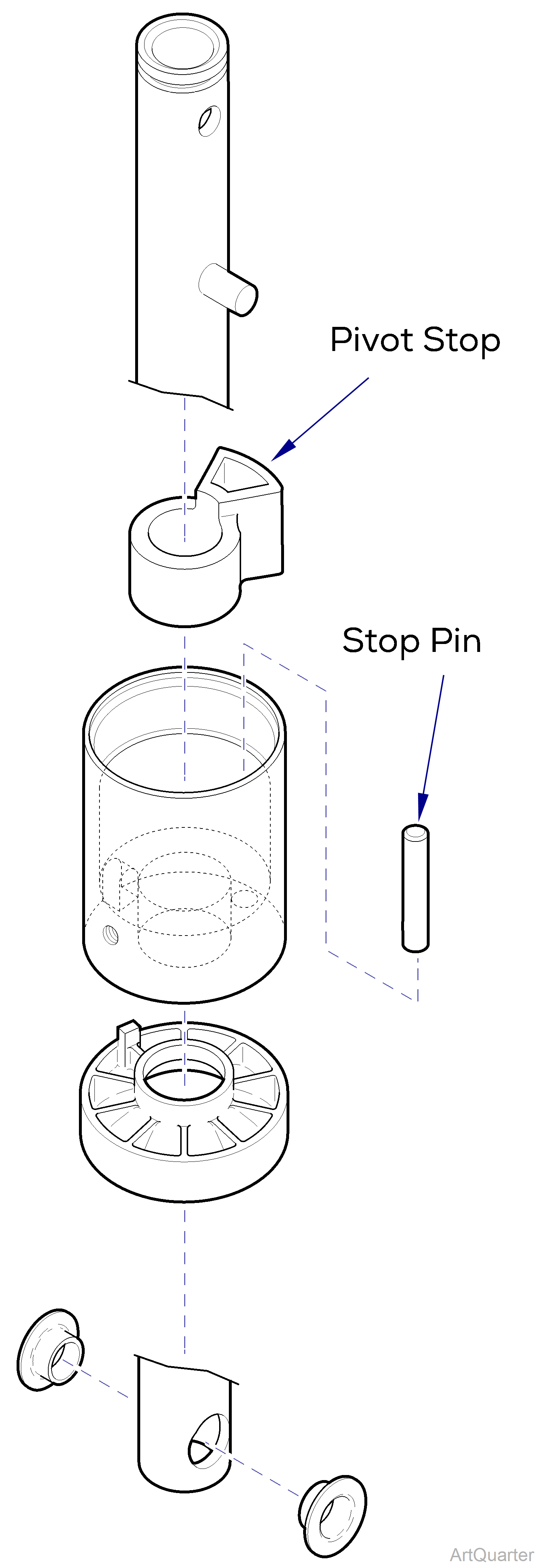

1.Remove two flange bearings.

2.Disassemble shaft / housing components.

3.Inspect stop pin. Replace if necessary.

4.Install pivot stop with raised portion facing up, housing, and brake onto shaft.

5.Install two flange bearings into shaft.