M3 Sterilizer Theory of Operation

During the Select Cycle Mode, the user chooses the appropriate sterilization cycle for a load. The Select Cycle Mode ends when the cycle has been chosen and the Start button is pressed.

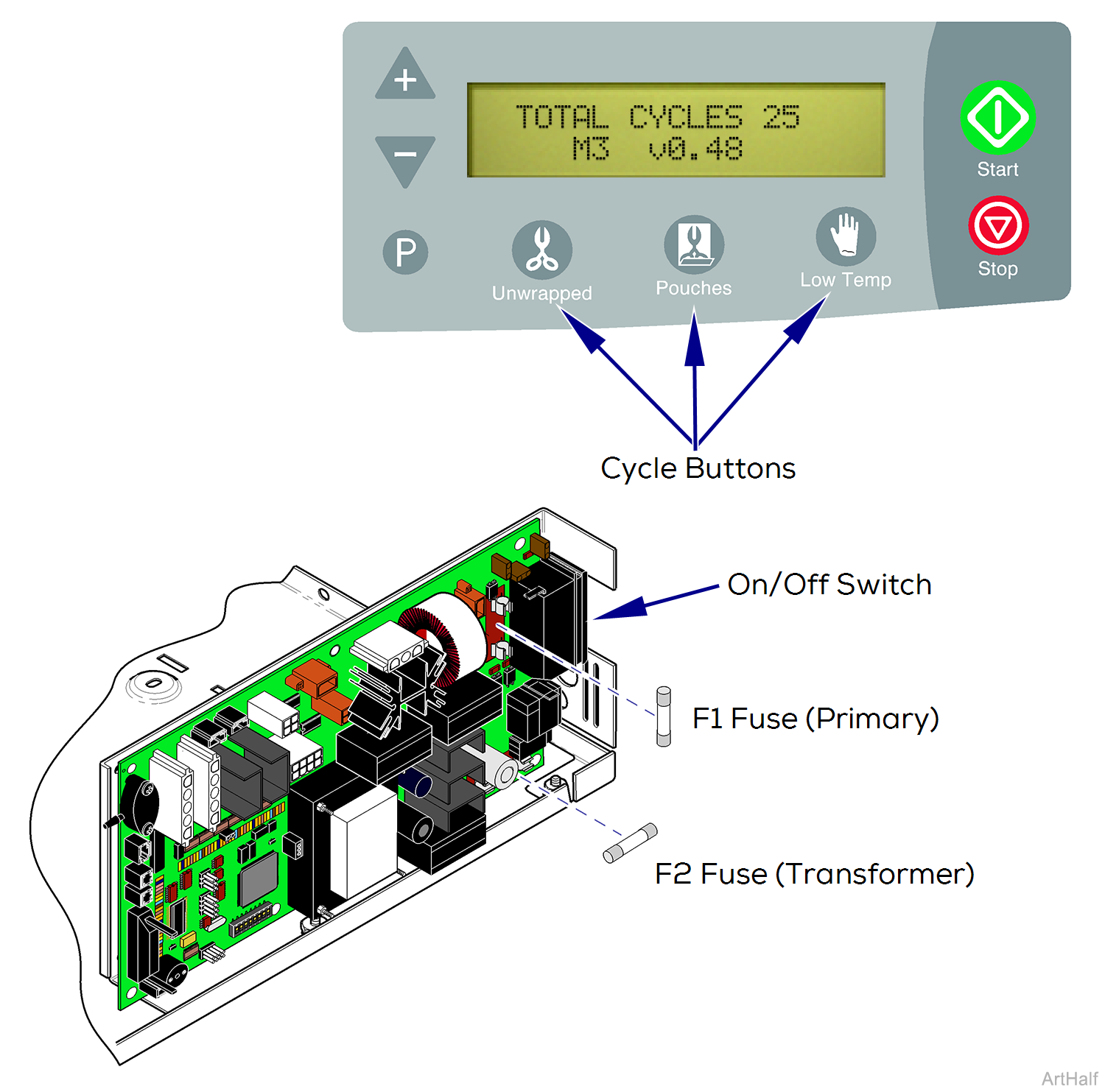

With the power cord properly connected

Line voltage is supplied to the power switch. When the switch is ON, power is supplied to the PC board thru F1 fuse.

F2 fuse provides protection for PC board transformer.

Any time the unit is powered On, the display will show the total number of cycles run on the sterilizer, the model number and the software version.

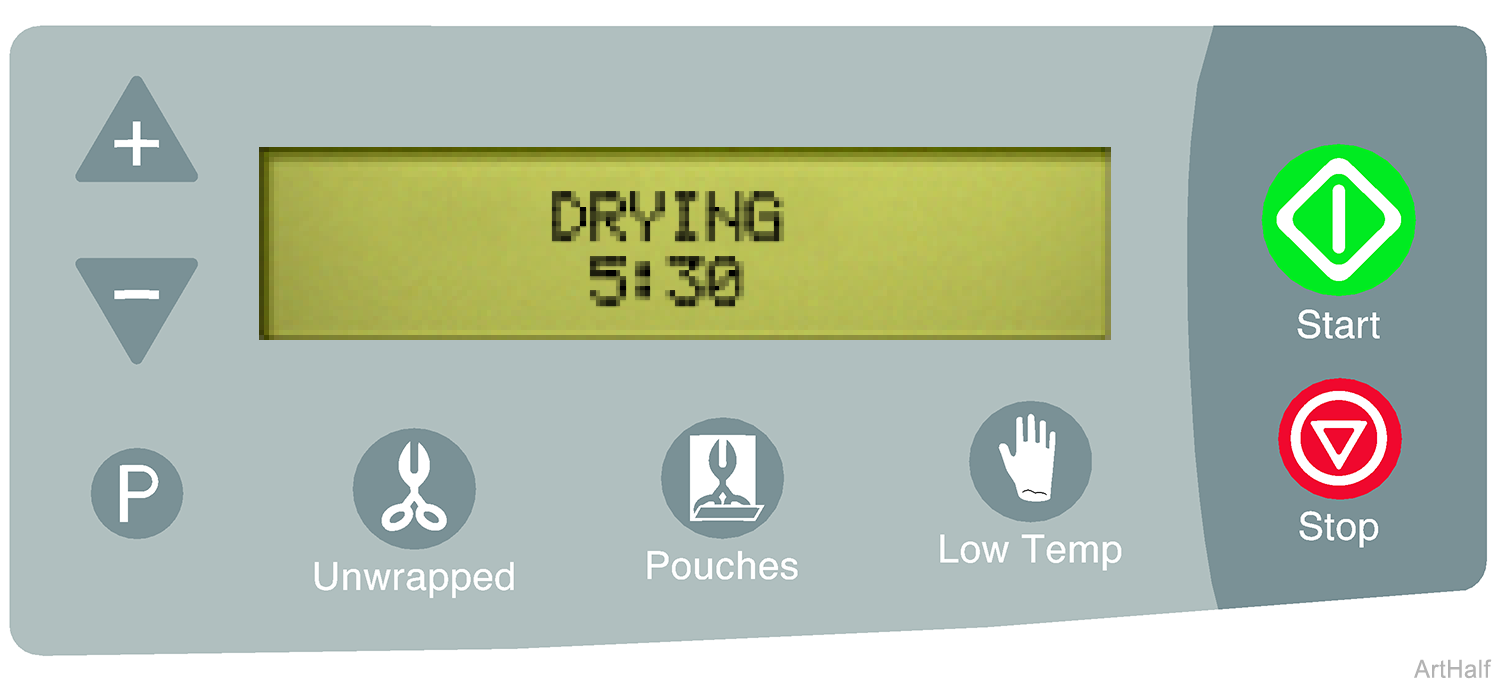

When the display shows, 'Select Cycle' the unit is ready for the user to press the desired cycle button.

When a cycle button is pressed, the parameters for the selected cycle are displayed (temperature / sterilization time / drying time).

Pressing the Start button initiates the Door Close Mode.

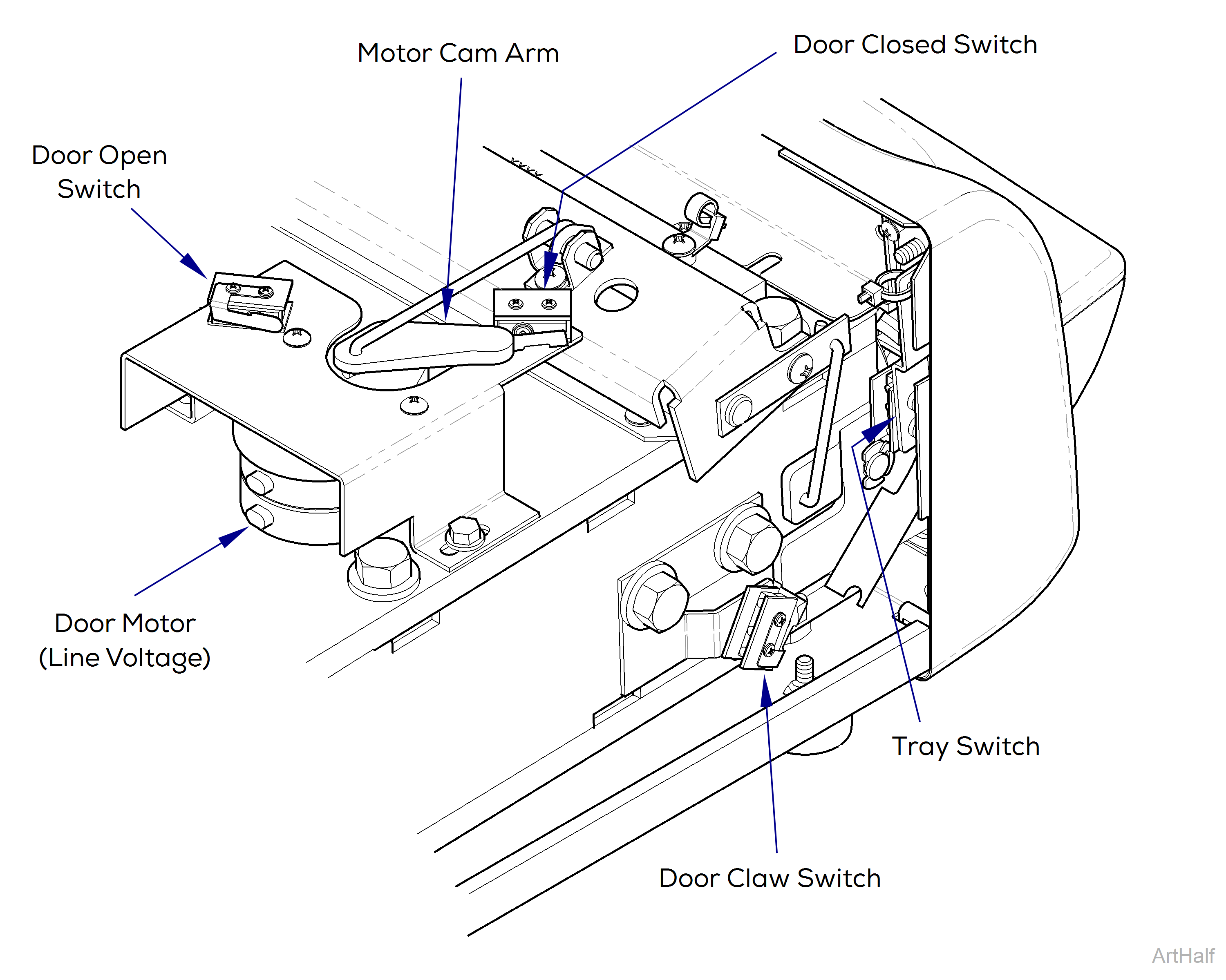

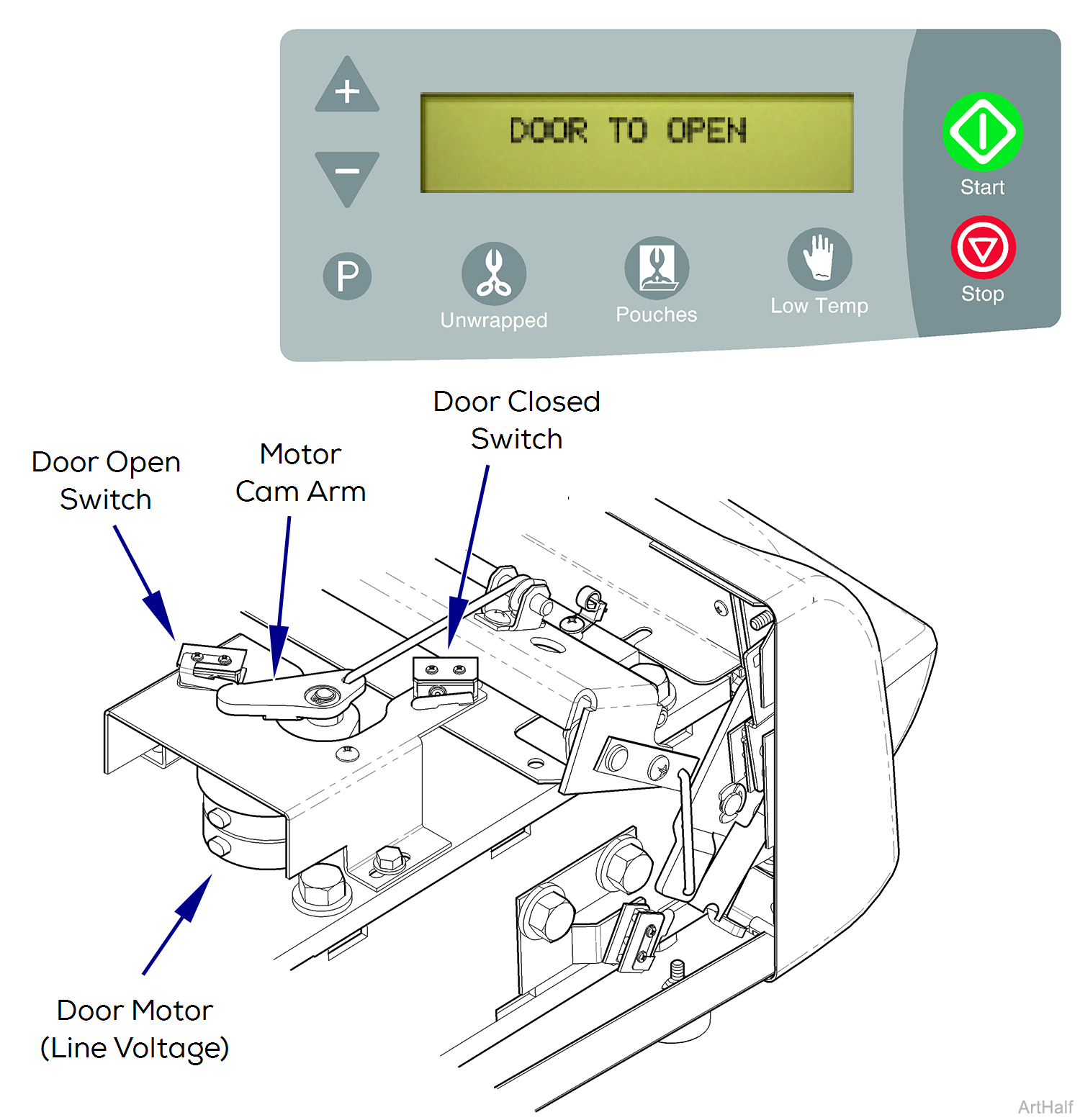

During the Door Close Mode, the door motor system is activated to lock the tray in position. The Door Close Mode ends when the door claw switch is tripped.

Tray switch

The PC board monitors the status of the normally open tray switch. With the tray in proper position, this switch is tripped and the Door Close Mode is initiated.

If the tray switch is not tripped, the display will show 'Tray not in Position' until the tray has been properly installed.

Door Motor

When the Door Close Mode is initiated, the door motor is activated. As the door motor runs, the cam arm and connected linkage rotate the door claws into the locked position to secure the tray assembly. The motor runs until the cam arm trips the Door Closed Switch.

Door Position Switches

The two door position switches Door Open and Door Closed monitor the position of the door motor cam arm. During the Door Close Mode, the motor cam arm rotates counter-clockwise. When the cam arm contacts the Door Close Switch, the switch opens and the door motor stops running.

Door Claw Switch

The Door Claw Switch is tripped when the claws reach the locked position. When this switch is tripped, the display will show 'Chamber Closed' and the Heat Up Mode is initiated.

Both the Door Closed Switch and the Door Claw Switch must be actuated for the heat up mode to start.

Other component(s) that are monitored

Water Level Sensor: if reservoir level is low, an error will result

Ext. Condensing Tank Sensors: if tank is full, an error will result

Other component(s) that are energized

Vent Valve: Open

Condensate Heater: On

Boiler: energized based on boiler temperature <270° F = On and >270° F = Off

During the Heat Up Mode, the steam temperature in the chamber is brought up to the sterilization set point for the selected cycle. The Heat Up Mode ends when the chamber reaches the sterilization temperature for selected cycle.

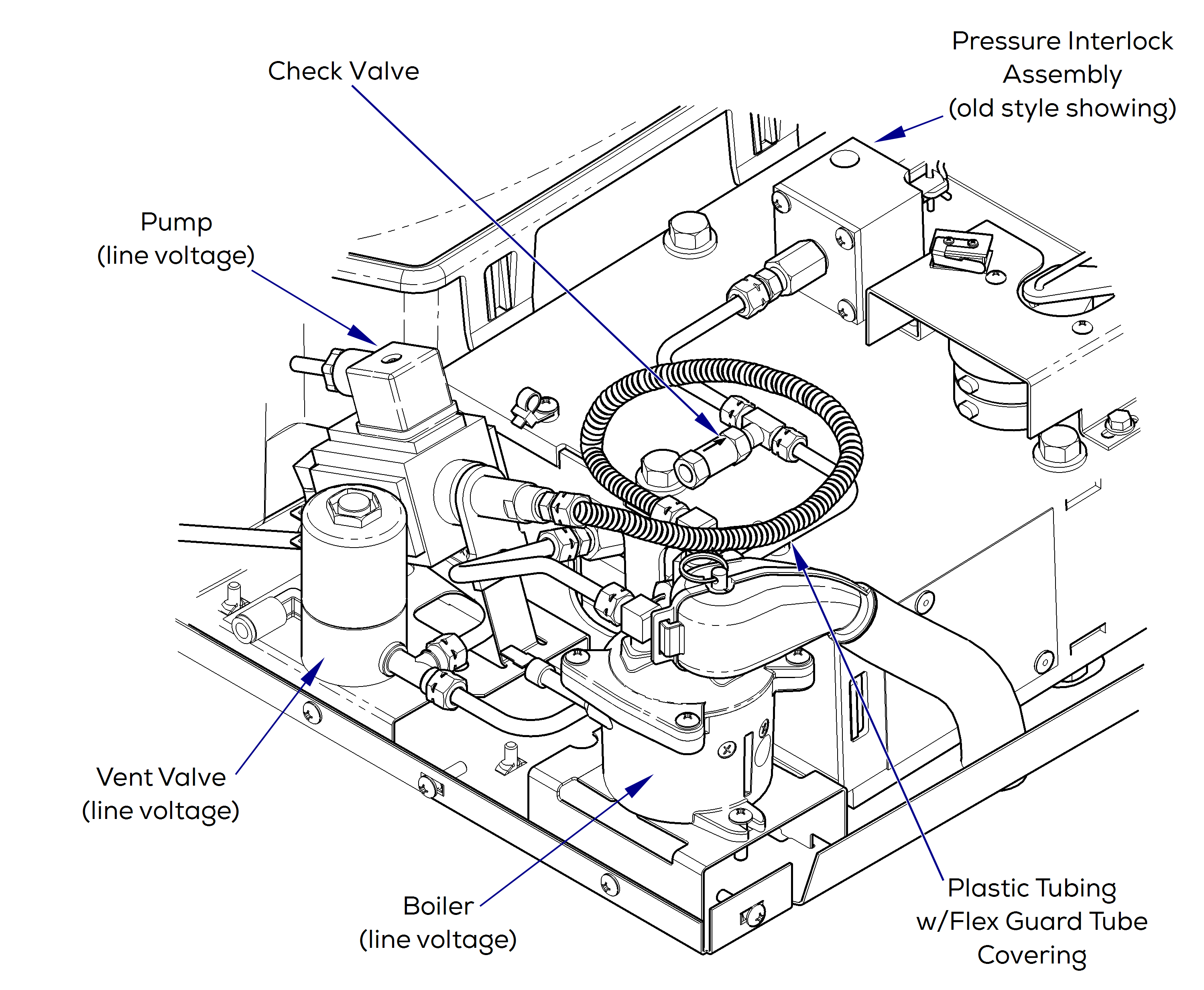

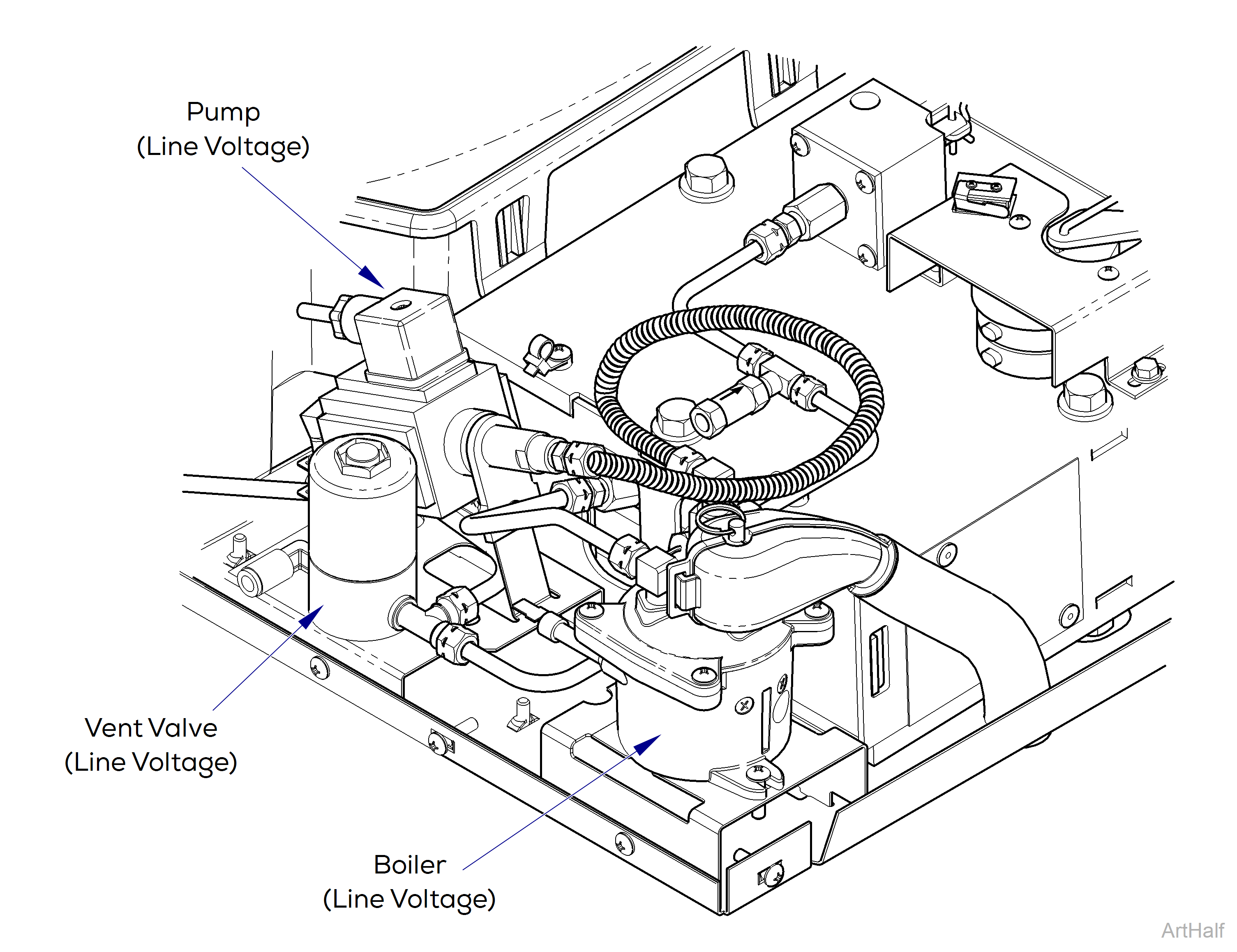

Pump

Throughout the Heat Up Mode, the pump is energized periodically based on control temperatures and time. When activated, the pump squirts water from the reservoir into the pre-heated boiler.

At the beginning of the Heat Up Mode, the pump is activated for 1.5 seconds, then OFF for approximately 12 seconds. After 12 seconds, the pump begins "normal operation", wherein the pump is cycled On/Off at preset intervals based on the temperature inside the boiler.

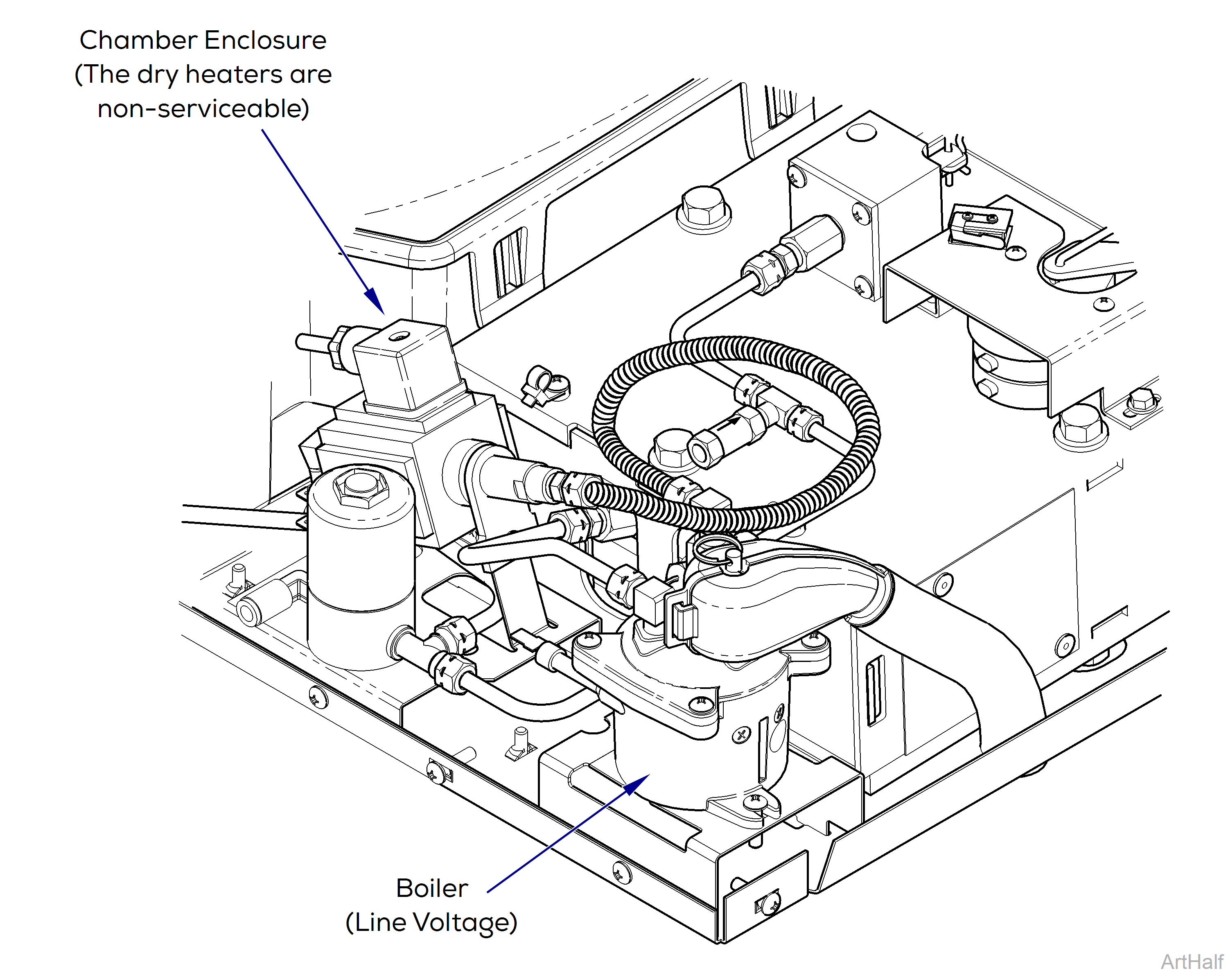

Boiler

The boiler is designed to heat the water pumped in from the reservoir, creating steam to pressurize the chamber.

The boiler is energized based on the temperature readings from the boiler temperature sensor. The target temperature for the boiler is approximately 18° F above the sterilization temperature for the selected cycle. The boiler cycles On/Off to maintain this target temperature.

Vent Valve

Throughout the Heat Up Mode, the vent valve is energized periodically based on chamber pressure, chamber temperature and time. When activated, the vent valve opens to purge air from the chamber.

At the beginning of the Heat Up Mode, the vent valve opens until chamber temperature reaches 212° F then closes. The vent valve remains closed until chamber conditions are appropriate for venting.

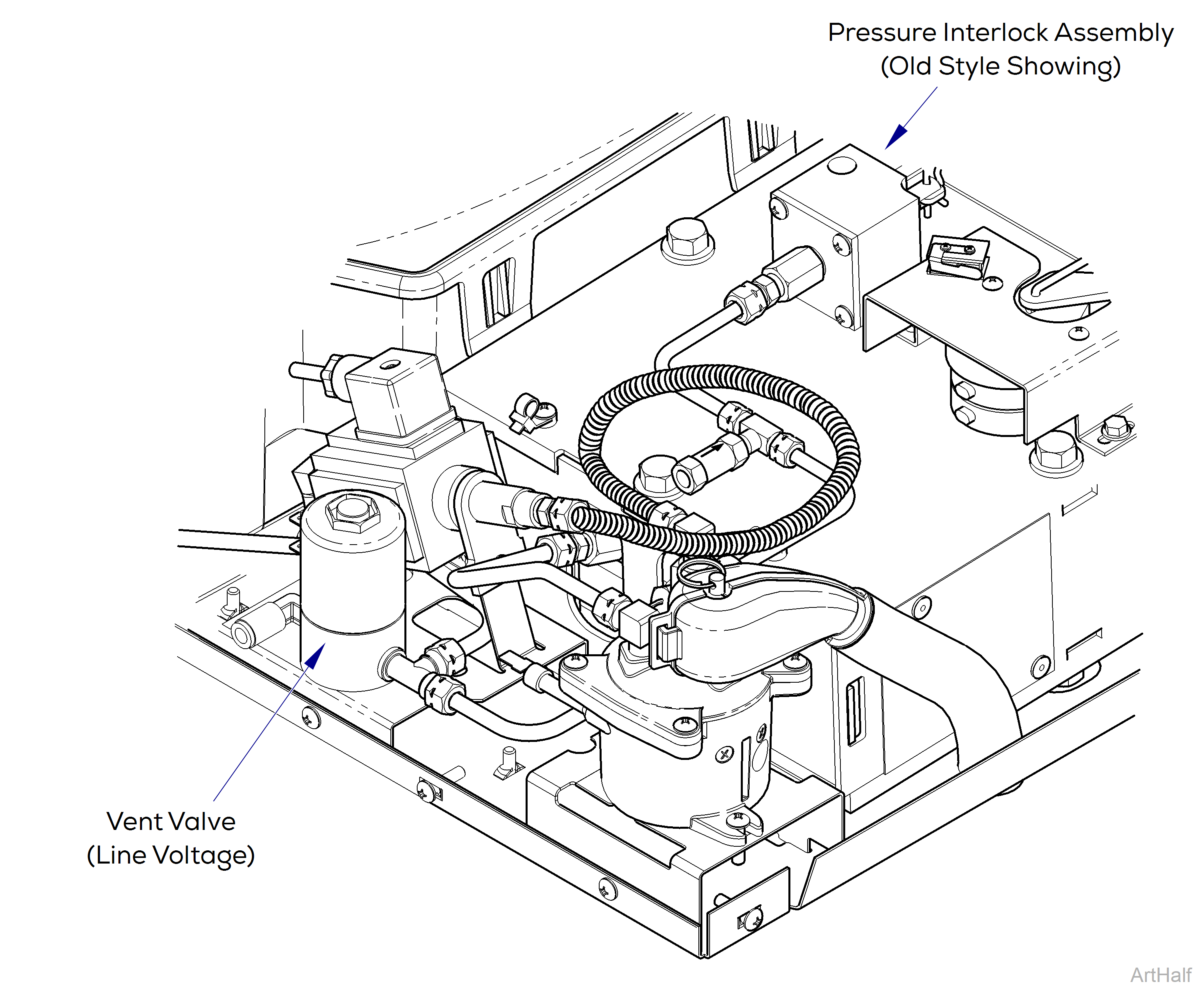

Pressure Interlock Assembly

The pressure interlock assembly prevents the door from opening while the chamber is pressurized. When the pressure in the chamber reaches approximately 4 - 6 PSI, the plunger extends, not allowing the door to open.

Units with photo interrupter installed, will not allow the door to open until the interlock is retracted to the unpressurized position.

Check Valve

The Check Valve will close as pressure builds in the chamber. In the event the power is interrupted during heat up or sterilization and the unit cools off with the door closed the check valve will open to prevent water from being siphoned from the reservoir into the chamber. The valve is directional, please note arrow if replacing.

Other component(s) that are energized: Condensate Heater: ON

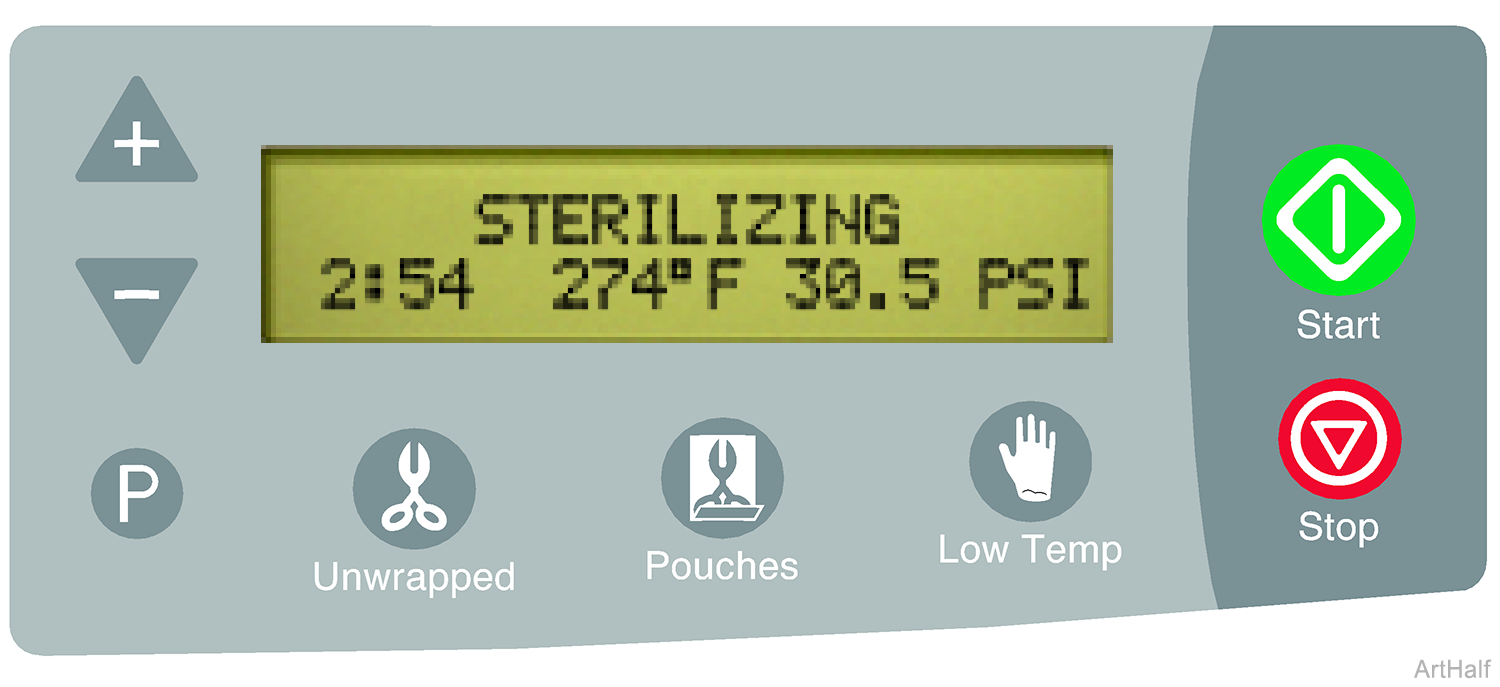

During the Sterilization Mode, the steam temperature in the chamber is maintained at the preset parameters (temperature and time) for the selected cycle. The Sterilization Mode ends when the sterilization time for the selected cycle expires.

Pump

Throughout the Sterilization Mode, the pump is energized periodically based on control temperatures and time. When activated, the pump quirts water from the reservoir into the pre-heated boiler.

Boiler

The boiler heats the water pumped in from the reservoir, creating steam to pressurize the chamber and maintain sterilization temperature.

The boiler is energized based on the temperature readings from the boiler temperature sensor. The target temperature for the boiler is approximately 18° F above the sterilization temperature for the selected cycle. The boiler cycles On/Off to maintain this target temperature.

Vent Valve

Throughout the Sterilization Mode, the vent valve is energized periodically based on control temperatures and time. When activated, the vent valve opens to purge air from the chamber.

Other component(s) that are energized: Condensate Heater: On

During the Vent Mode, the pressure in the chamber is released thru the vent valve. This reduces the temperature and creates a safe condition to open the door. The vent mode ends when the chamber pressure drops below 1.0 PSI.

Vent Valve

The vent valve is activated throughout the entire Vent Mode. When activated, the vent valve opens, releasing the steam pressure from the chamber.

The pressure in the chamber forces the steam thru the open vent valve. The steam condenses as it passes thru the vent tubing and condensing coil. The resulting water is collected in the condensing tank.

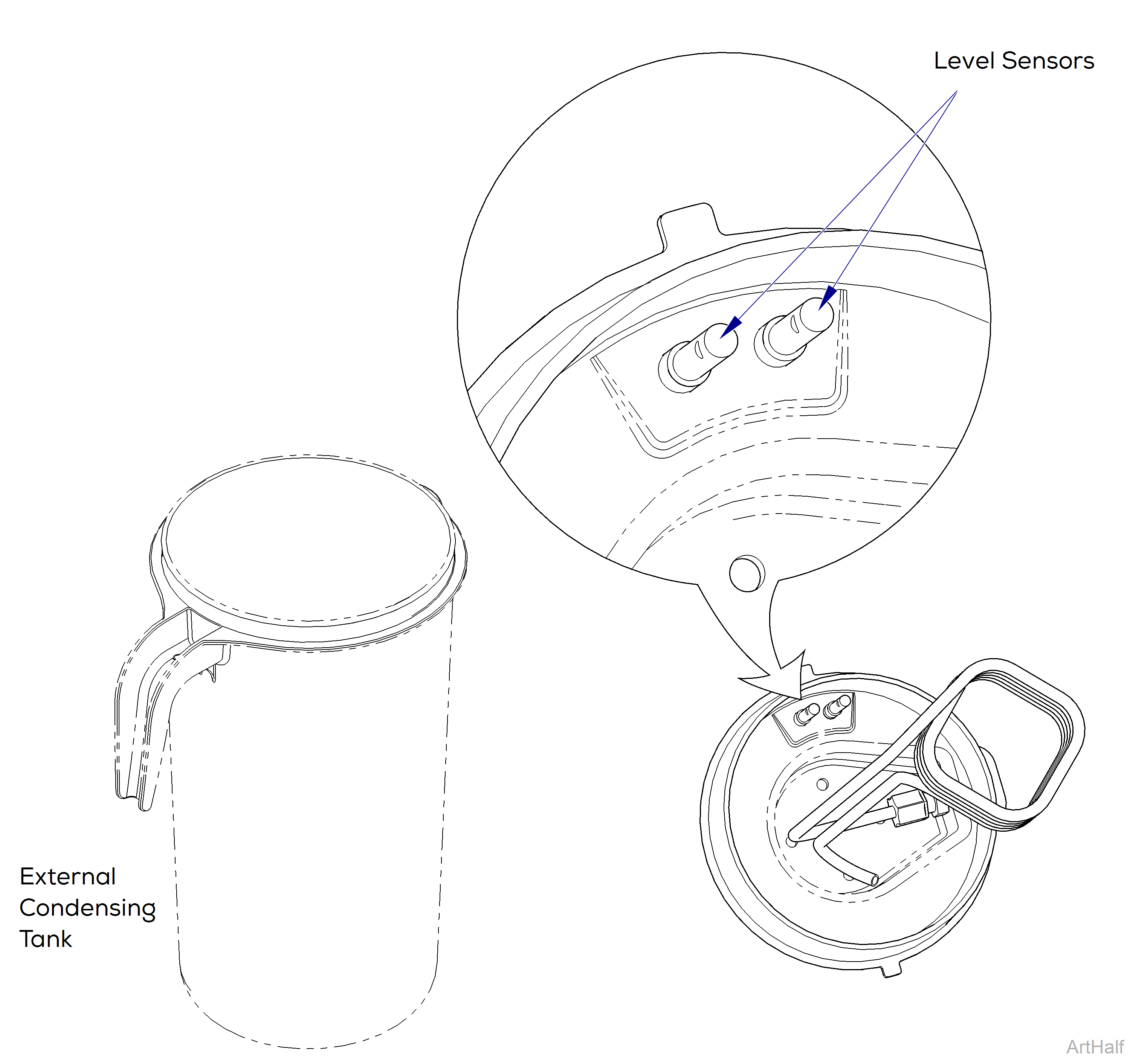

External Condensing Tank

The condensing coil attached to the tank lid, cools the steam when it is released thru the vent valve. The tank collects the condensation that is produced.

There are two level sensors on the tank lid to monitor the amount of water in the tank. When the water level reaches the sensors, the completed circuit produces an error message on the display* "External Tank Full".

*The error message will not appear until the start of the next cycle.

Pressure Interlock Assembly

When the pressure in the chamber drops to approximately 2 - 3 PSI, the assembly plunger retracts in preparation for the door opening mode. On units with photo interrupter installed, the door will not start to open until the photo interrupter indicates the pressure interlock is disengaged.

Other component(s) that are energized: Condensate Heater: ON

During the Door Open Mode, the door motor system is activated to open the door (unlock tray). The Door Open Mode ends when the door open switch is tripped.

Door Motor

When the Door Open Mode is initiated, the door motor is activated. As the door motor runs, the cam arm and connected linkage rotate the door claws to the unlocked position to release the tray assembly. The motor runs until the cam arm trips the Door Open switch.

Door Position Switches

The two door position switches, Door Open and Door Closed, monitor the position of the door motor cam arm. During the Door Open Mode, the motor cam arm rotates clockwise.

When the cam arm contacts the Door Open Switch, the switch opens and the door motor stops running.

Other component(s) that are energized: Condensate Heater: ON

The display will count down the drying time.

During the Dry Mode, heat is applied to the chamber to dry the load at the end of the cycle. The Dry Mode ends when the specified dry time expires.

The maximum dry temperature in the Unwrapped and Pouches cycle is 250° F to 260° F.

The maximum dry temperature in the Low Temp cycle is 245° F to 250° F.

Dry Heaters

The dry heaters are inaccessible and non-serviceable.

There are two dry heaters mounted inside the chamber enclosure. They provide heat to dry the load at the end of a cycle.

Both heaters are energized intermittently based on a temperature regulation algorithm to maintain the target temperature for the selected cycle. When the dry time has expired, the dry heaters are turned OFF.

During the dry mode, the board is monitoring the tray switch. If it opens the drying mode is stopped.

Boiler

SN V1524268 thru Present Models Only: The boiler is energized continuously for the first 30 seconds of Dry Mode if the temperature is <240° F.

During the remainder of Dry Mode, the boiler is energized periodically based on the boiler temperature and the status of the dry heaters.

The boiler is ON if dry heaters are OFF and boiler temperature is < 240° F.

The boiler is OFF if dry heaters are ON or boiler temperature is > 240° F.

Other component(s) that are energized: Condensate Heater: ON