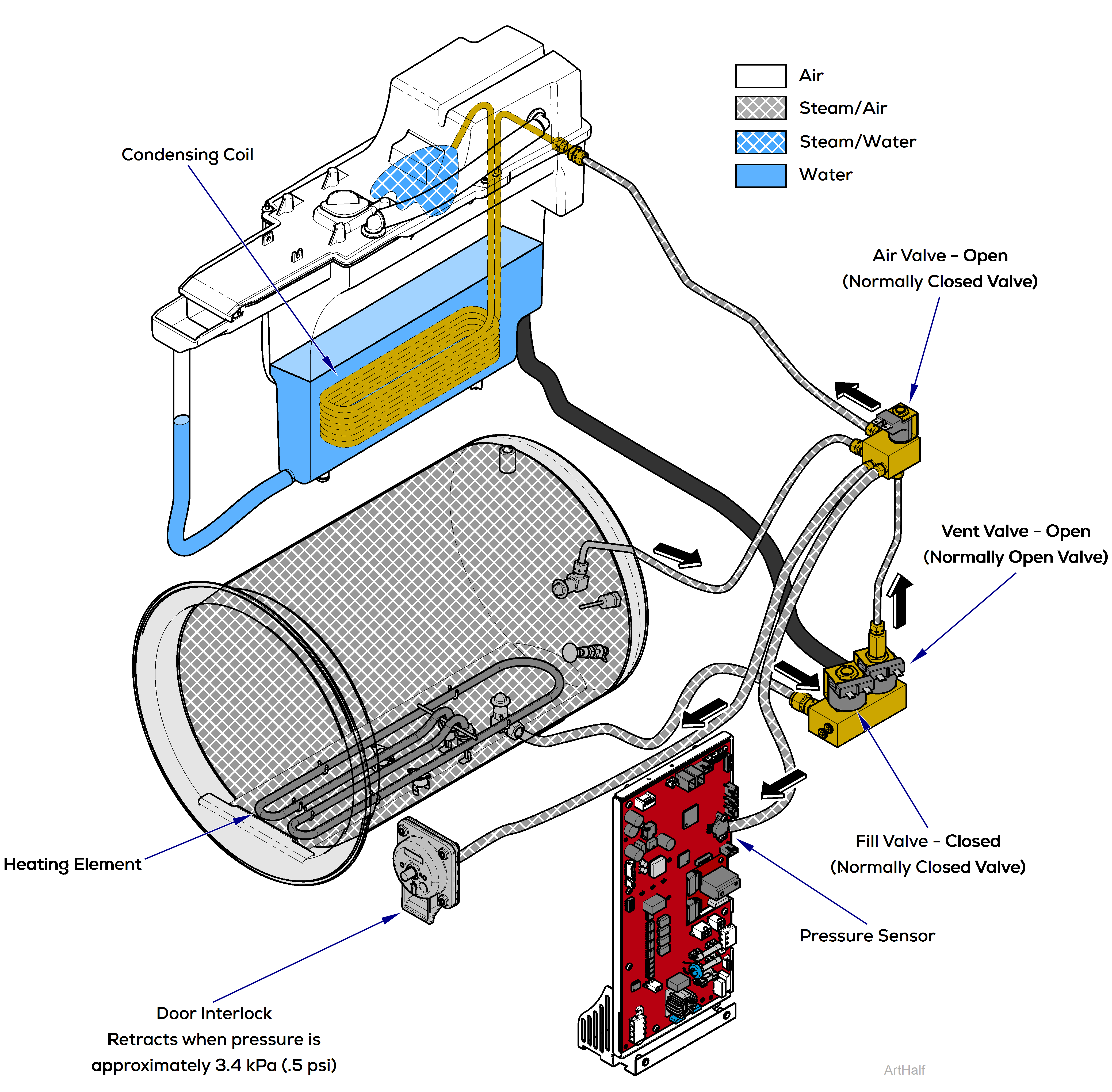

Midmark M9® -05x / M11® -05x Sterilizer Flow Diagram

To prevent risk of shock always disconnect power before removing covers or performing any service procedure.

Some procedures require power to be connected with covers removed. Line voltage is present. Use extreme caution to prevent electric shock.

|

Model |

M9 -050, -053 | M11 -050, -051, -053 |

| Serial Number | All | All |

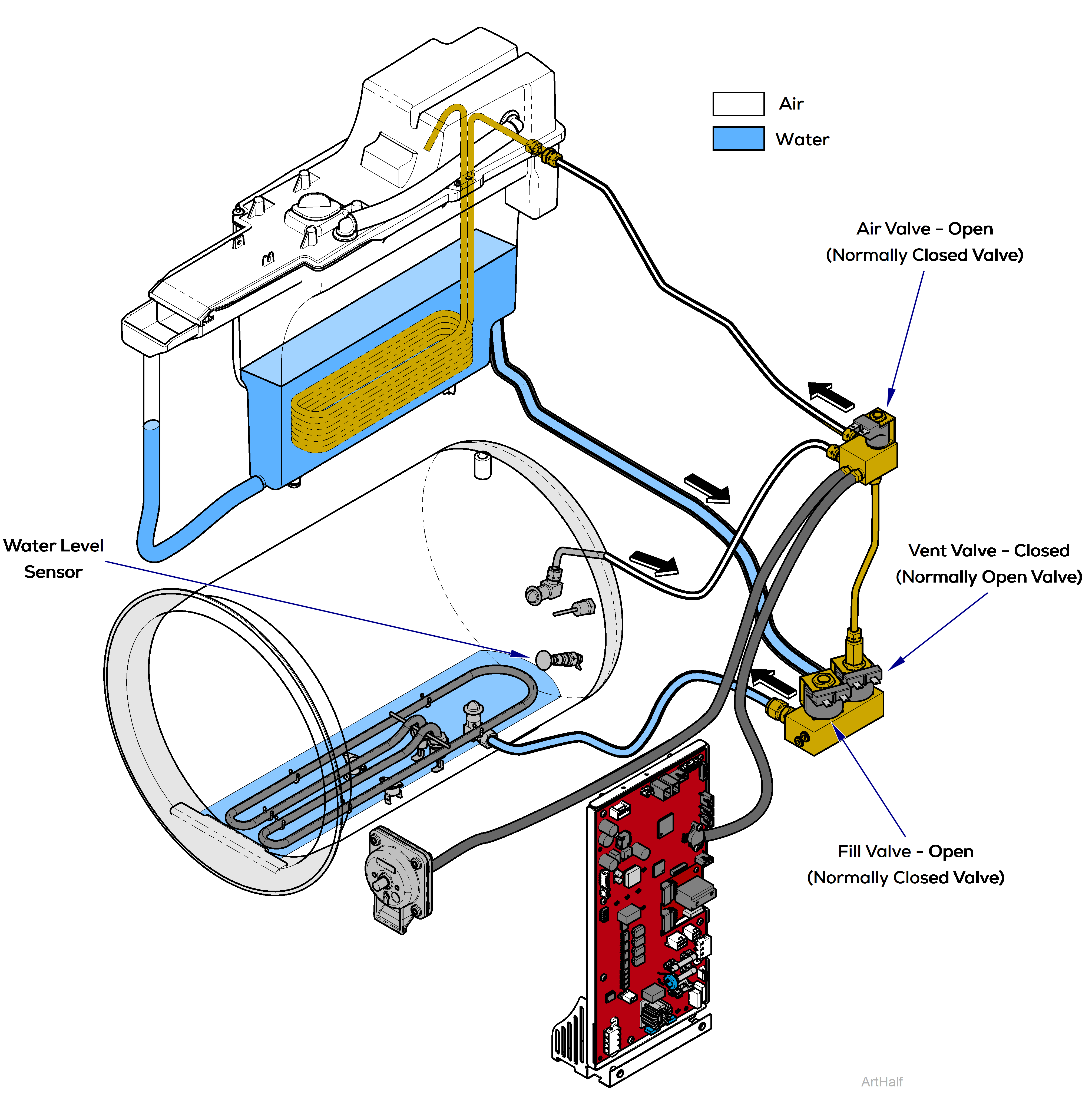

During the Filling mode, water flows from the reservoir, through the fill valve into the chamber.

Air Valve

The air valve opens. This allows air to pass through the valve so that water can flow from the reservoir.

Vent Valve

The (normally open) vent valve is closed. This prevents water from flowing back into the reservoir through the vent valve.

Fill Valve

The fill valve opens allowing water to flow from the reservoir into the chamber.

Water Level Sensor

When the water level in the chamber reaches the water level sensor, the PC Board shuts off the fill valve, stopping the flow of water into the chamber.

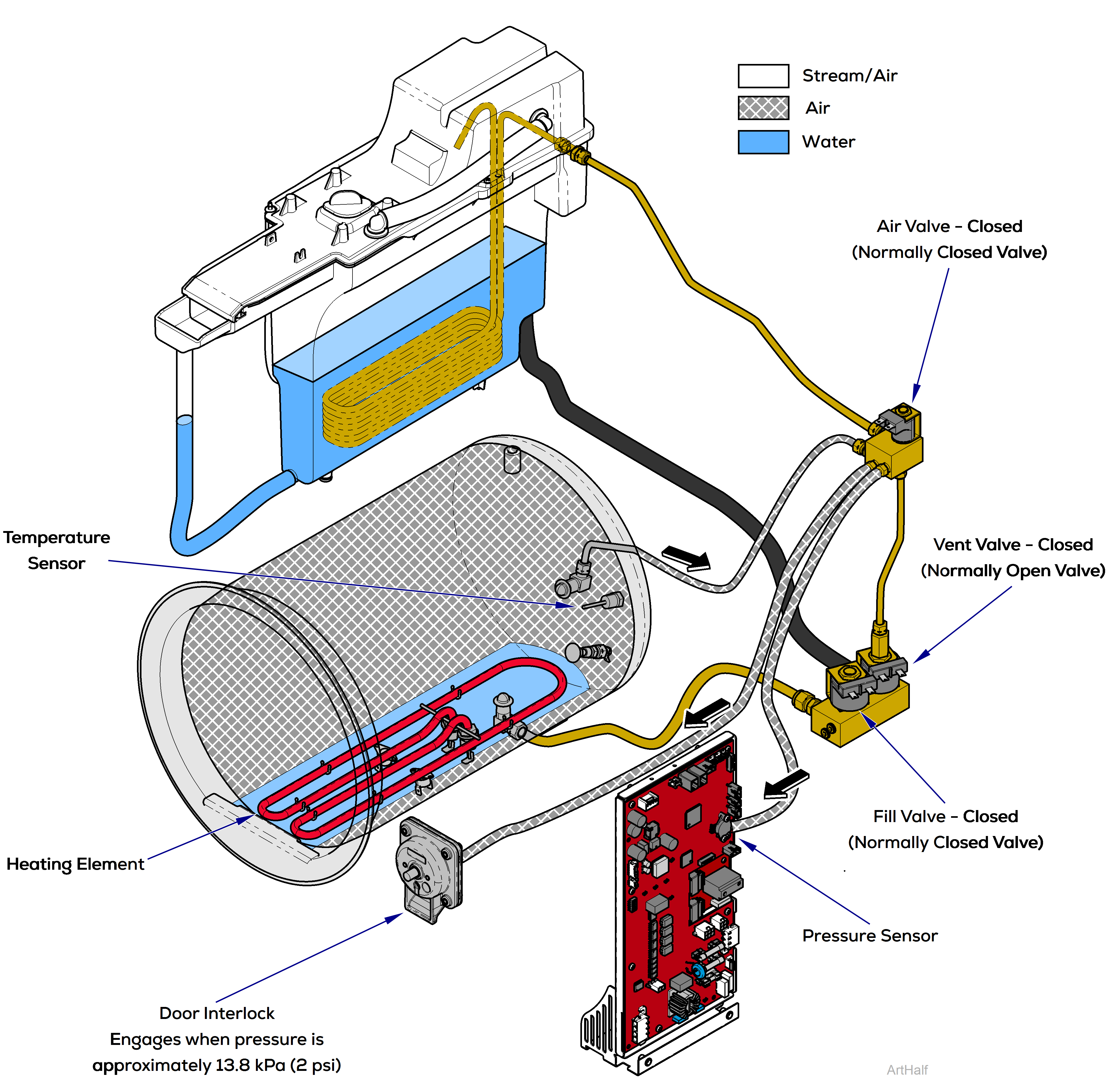

During the Heating mode, the water in the chamber is heated to achieve the proper temperature and pressure for sterilization.

Heating Element

The heating element is turned on heating the water in the chamber until sterilization temperature and pressure conditions are achieved.

Vent Valve

The (normally open) vent valve is closed. This prevents water from flowing back into the reservoir through the vent valve.

Temperature Sensor and Pressure Sensor

The temperature sensor (inside chamber) and pressure sensor (on Main PC Board) monitor the conditions inside the chamber. When the pre-set sterilization conditions are met, the Heating mode is complete.

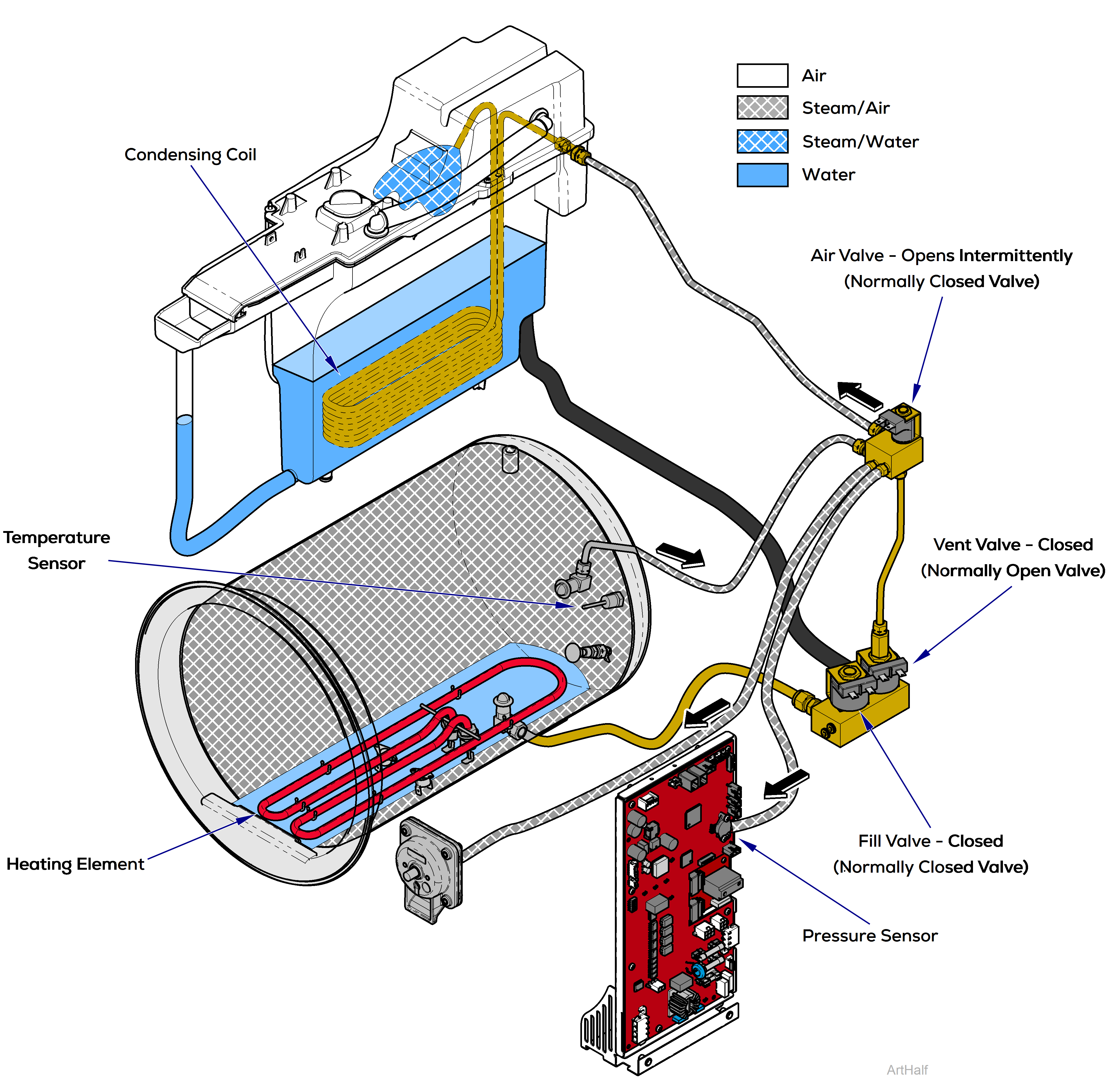

During the Purging mode, the water in the chamber continues to be heated to achieve the proper temperature and pressure for sterilization. The air valve periodically opens to expel air from the chamber.

Heating Element

The heating element stays on heating the water in the chamber until sterilization temperature and pressure conditions are achieved.

Vent Valve

The (normally open) vent valve is energized closed. This prevents water from flowing back into the reservoir thru the vent valve.

Air Valve

During purging the air valve periodically opens.

•Wrapped 1 and Wrapped 2:

Air valve will initially open until the chamber temperature reaches 87.8 °C (190 °F). Once closed, the air valve will be opened four times to expel air from the chamber.

•Unwrapped and Delicate:

Air valve will initially be closed, opening three times to expel air from the chamber.

Condensing Coil

During the purges, steam released from the chamber is circulated through the condensing coil. This process cools the steam, converting it back into liquid, which is then returned to the reservoir.

Temperature Sensor and Pressure Sensor

The temperature sensor (inside chamber) and pressure sensor (on Main PC Board) monitor the conditions inside the chamber. When the pre-set sterilization conditions are met, purging is complete.

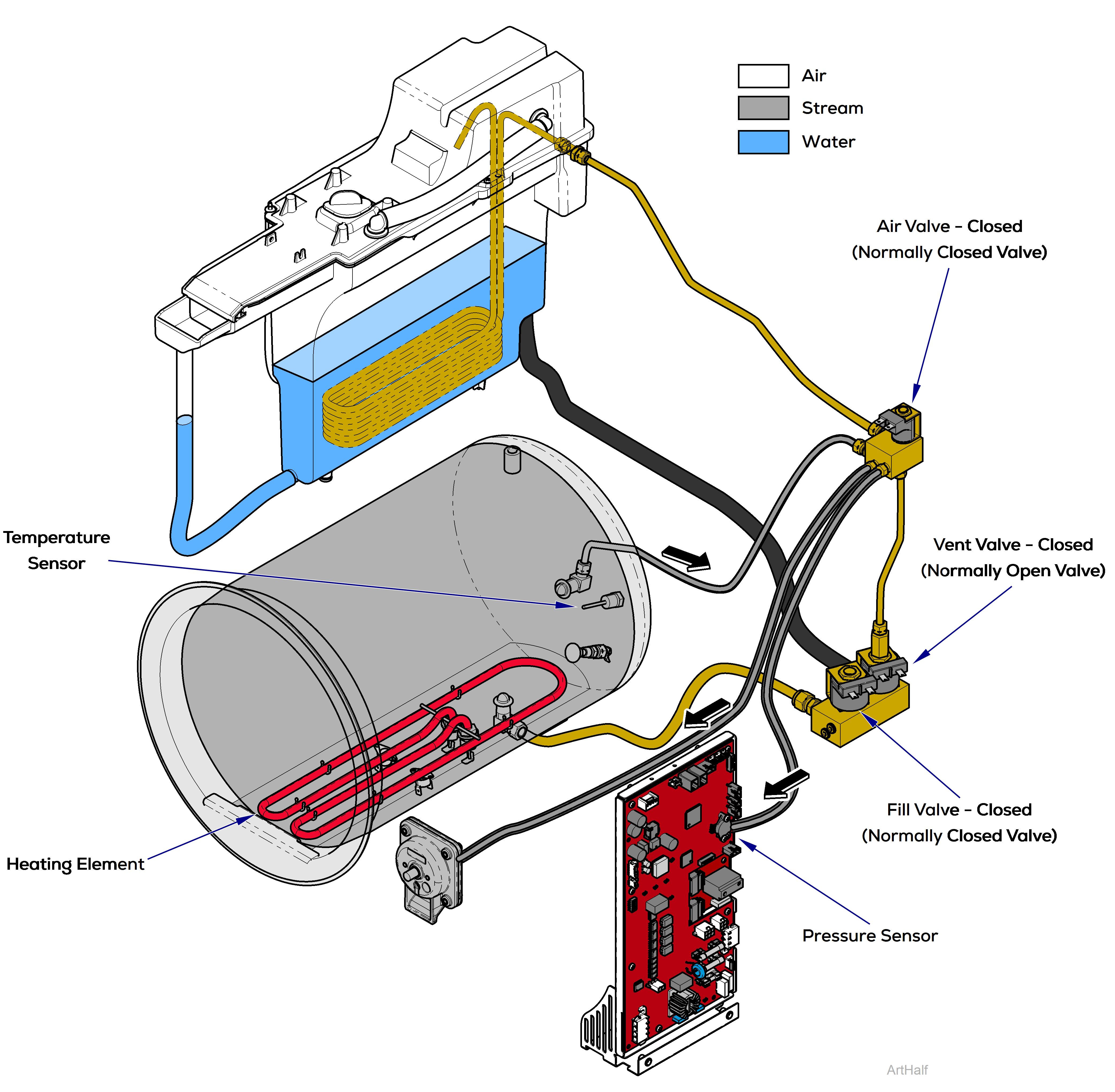

During the Sterilizing mode, the temperature and pressure parameters for the selected cycle are maintained for the required time.

Heating Element

Based on readings from the temperature sensor and pressure sensor, the heating element is cycled ON/OFF to maintain the required temperature and pressure for the selected cycle.

Vent Valve

The (normally open) vent valve is closed. This prevents water from flowing back into the reservoir through the vent valve.

Air Valve

The air valve is closed during sterilization. This prevents steam/pressure from escaping the chamber.

Temperature Sensor and Pressure Sensor

The temperature sensor (inside chamber) and pressure sensor (on Main PC Board) monitor the conditions inside the chamber throughout the Sterilizing mode.

During the Venting mode, steam and pressure are released from the chamber. The steam cools as it passes through the condensing coil, and the water is returned to the reservoir.

Air Valve

The air valve opens. This allows steam to pass through the valve back to the reservoir.

Vent Valve

The (normally open) vent valve opens allowing steam and water to pass through to the condensing coil.

Condensing Coil

During venting, steam released from the chamber is circulated through the condensing coil. This process cools the steam, converting it back into liquid, which is then returned to the reservoir.

Pressure Sensor

The pressure sensor (on Main PC Board) monitors the chamber pressure as it is released.