Midmark M9® -05x / M11® -05x Sterilizer Heating Element Test and Repair

To prevent risk of shock always disconnect power before removing covers or performing any service procedure.

Some procedures require power to be connected with covers removed. Line voltage is present. Use extreme caution to prevent electric shock.

|

Model |

M9 -050, -053 | M11 -050, -051, -053 |

| Serial Number | All | All |

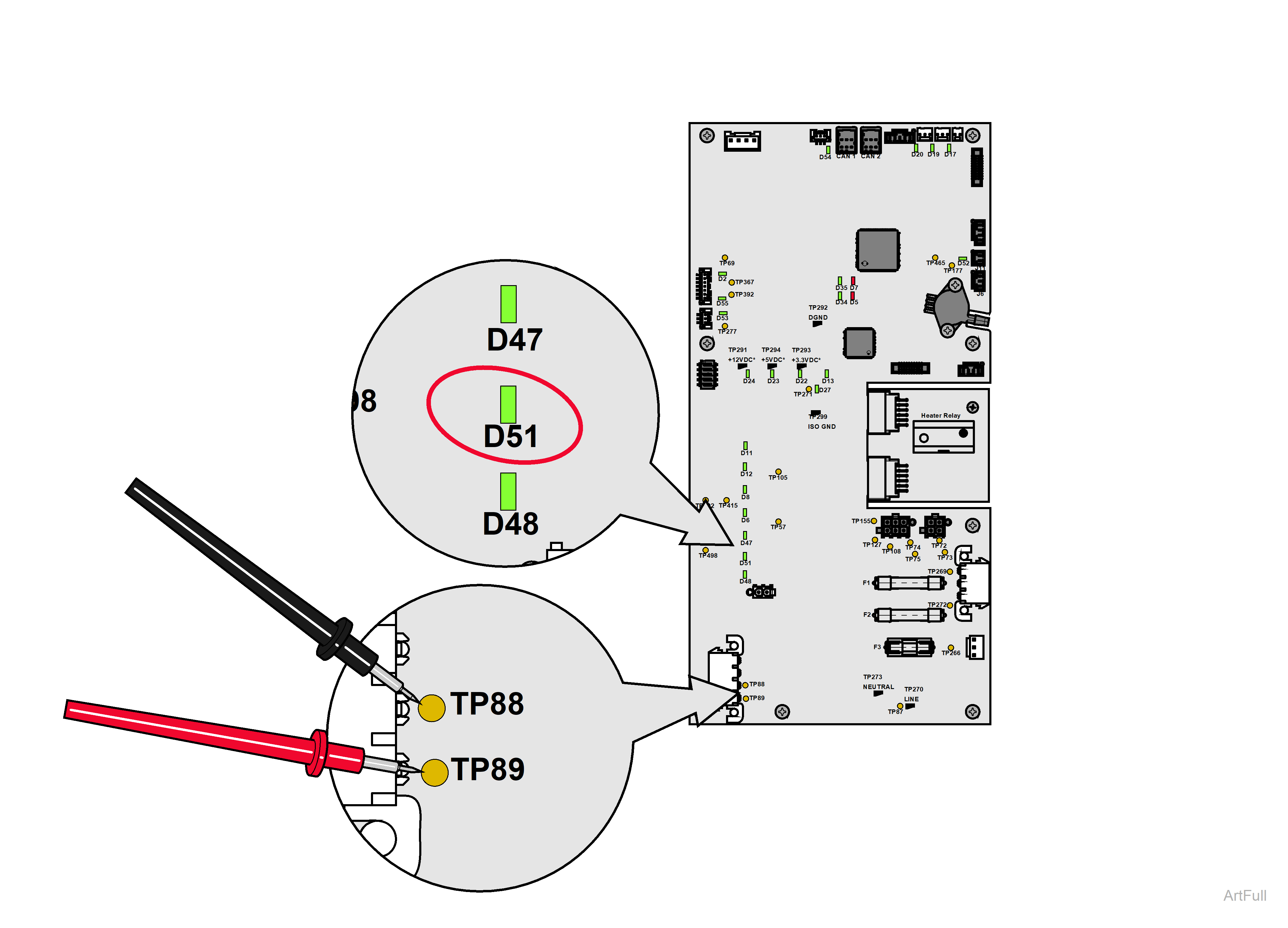

For proper test point readings, meter leads need to penetrate PC board conformal coating.

For proper voltage readings, the circuit must be connected (loaded) to the component—such as a solenoid valve you are checking.

1.Set meter to VAC.

2.Place meter probes on desired points and check reading.

Heater Output = TP89 and TP88

3.Energize the fan and check reading.

The corresponding LED should light up.

Heater Status = LED D51 on

|

Meter Reading |

Required Action |

|---|---|

|

Heater output activated and thermostats not tripped = approximately 115 VAC / 230 VAC |

PC board is OK. Perform Continuity Test. |

|

Not activated = approximately 0 VAC |

PC board is OK. Perform Continuity Test. |

|

Any other reading |

Replace PC board. |

Sterilizer or components may be hot or become hot. Wait until the sterilizer or components are cool to the touch before continuing service.

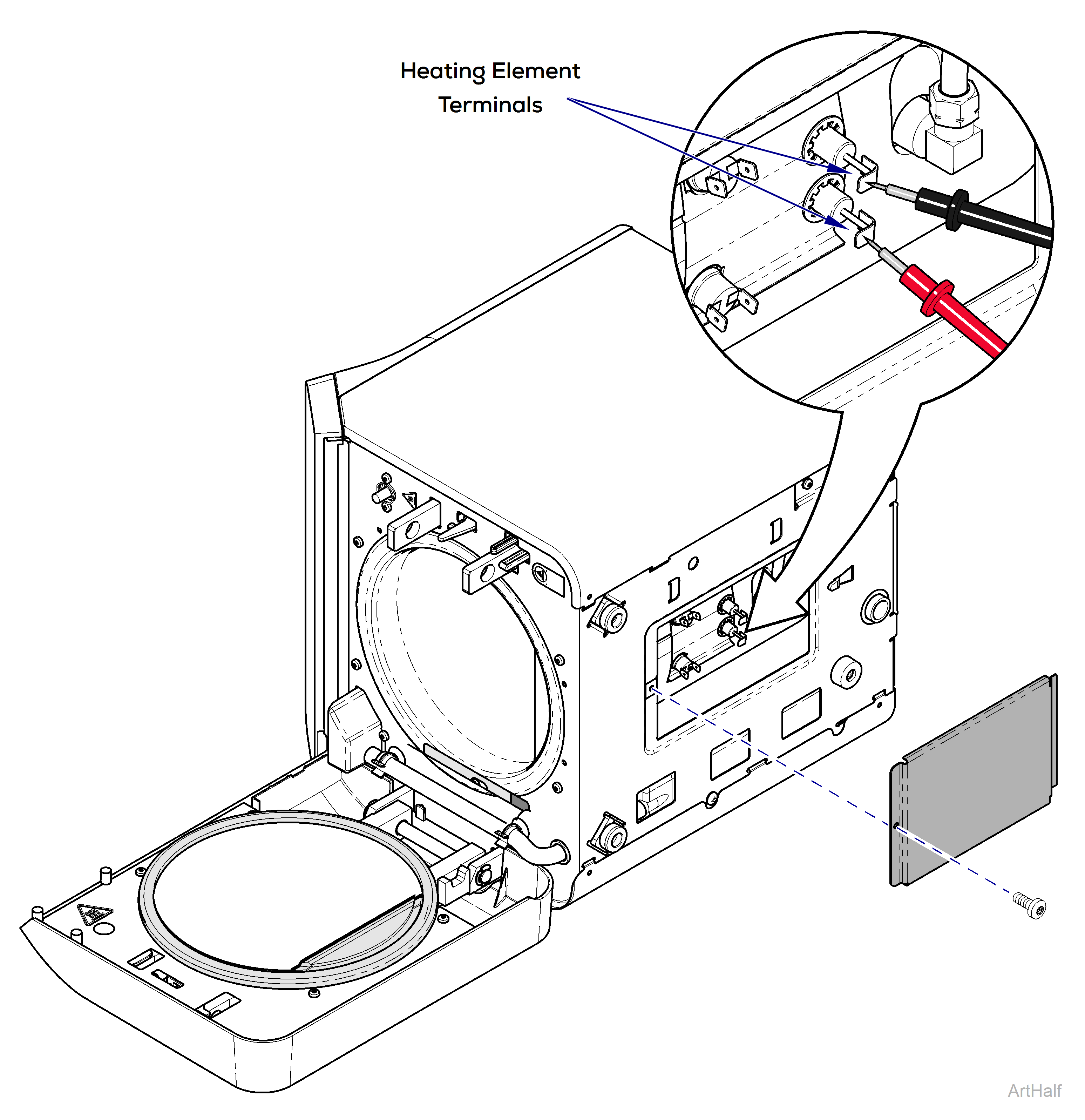

1.Disconnect power from sterilizer.

2. Drain water from reservoir.

3.Carefully lay sterilizer onto left side.

4.Remove screw and inspection cover.

5.Set meter to Ohms (Ω).

6.Disconnect wires from heating element terminals.

7.Place meter probes on heating element terminals.

|

Meter Reading |

Required Action |

|---|---|

|

115V models: 9 to 11 Ω |

Heating element is good. |

|

230V models: 34 to 42 Ω |

Heating element is good. |

| Any reading out of the acceptable range |

Replace heating element. |