Midmark M9® -05x / M11® -05x Sterilizer Heating Mode Theory of Operation

To prevent risk of shock always disconnect power before removing covers or performing any service procedure.

Some procedures require power to be connected with covers removed. Line voltage is present. Use extreme caution to prevent electric shock.

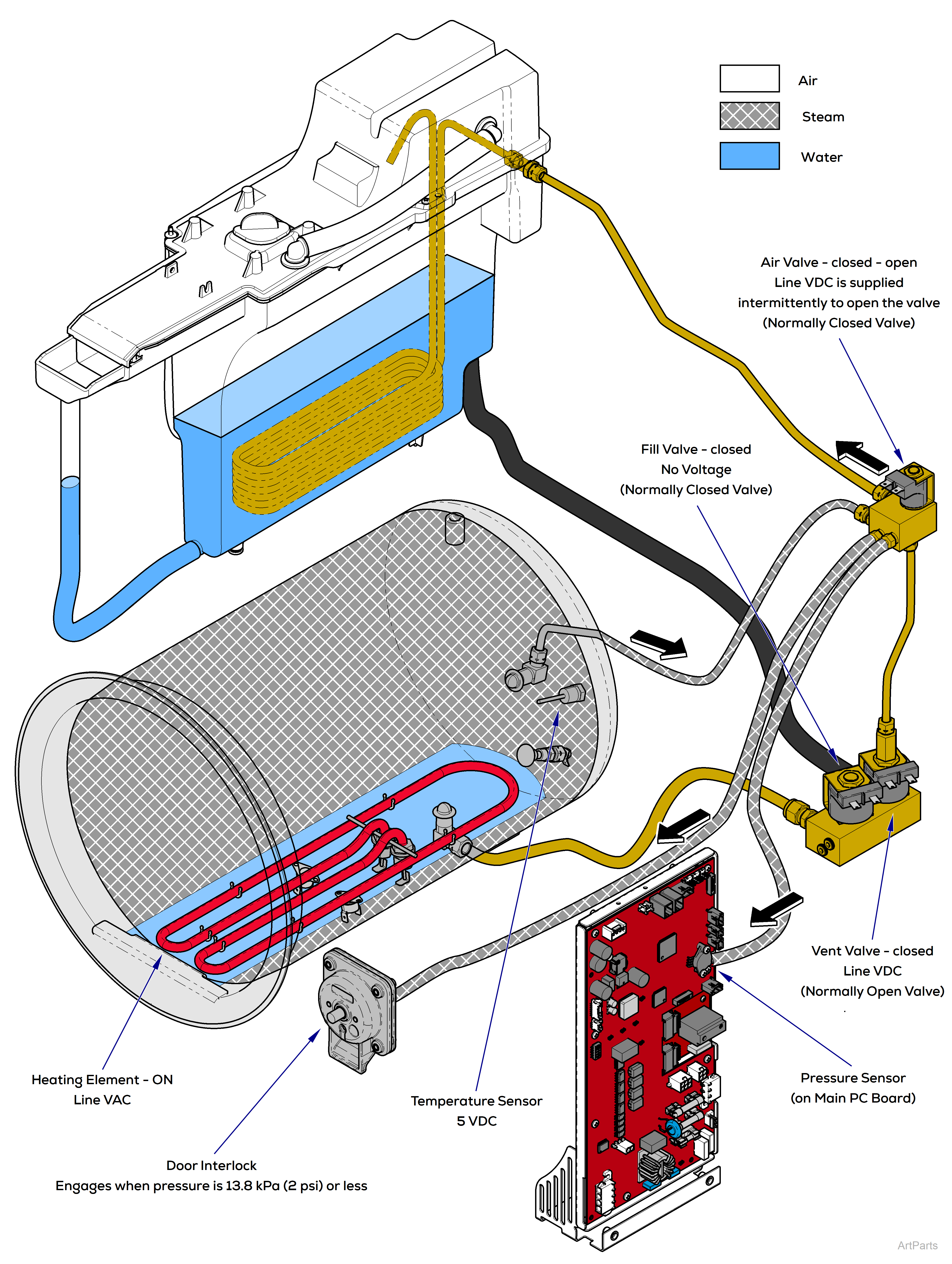

The illustration below calls out the components that are energized/monitored during the Heating mode. Refer to the dropdowns for detailed descriptions.

|

Model |

M9 -050, -053 | M11 -050, -051, -053 |

| Serial Number | All | All |

During the Heating mode, the water in the chamber is heated to achieve the proper temperature for sterilization.

Throughout the Heating mode, line voltage is continually supplied to the heating element. The heating element heats the water in the chamber until sterilization temperature and pressure conditions are achieved.

Throughout the Heating mode, voltage is supplied to the (normally open) vent valve. When energized, the vent valve closes. This prevents water from flowing back into the reservoir through the vent valve.

Periodically during the Heating mode, voltage is supplied to the (normally closed) air valve. When energized, the air valve opens.

•Wrapped 1 and Wrapped 2:

Air valve will initially be energized open until the chamber temperature reaches 87.8 °C (190 °F). Once closed, the air valve will be opened four times to expel air from the chamber.

•Unwrapped and Delicate:

Air valve will initially be closed. Opening occurs three times to expel air from the chamber.

The temperature sensor (inside chamber) and pressure sensor (on Main PC Board) monitor the conditions inside the chamber.

When the pre-set sterilization conditions are met, the Heat-Up Mode is complete, and the unit goes into the Sterilization Mode.