Midmark M9® -05x / M11® -05x Sterilizer Sterilization Mode Theory of Operation

To prevent risk of shock always disconnect power before removing covers or performing any service procedure.

Some procedures require power to be connected with covers removed. Line voltage is present. Use extreme caution to prevent electric shock.

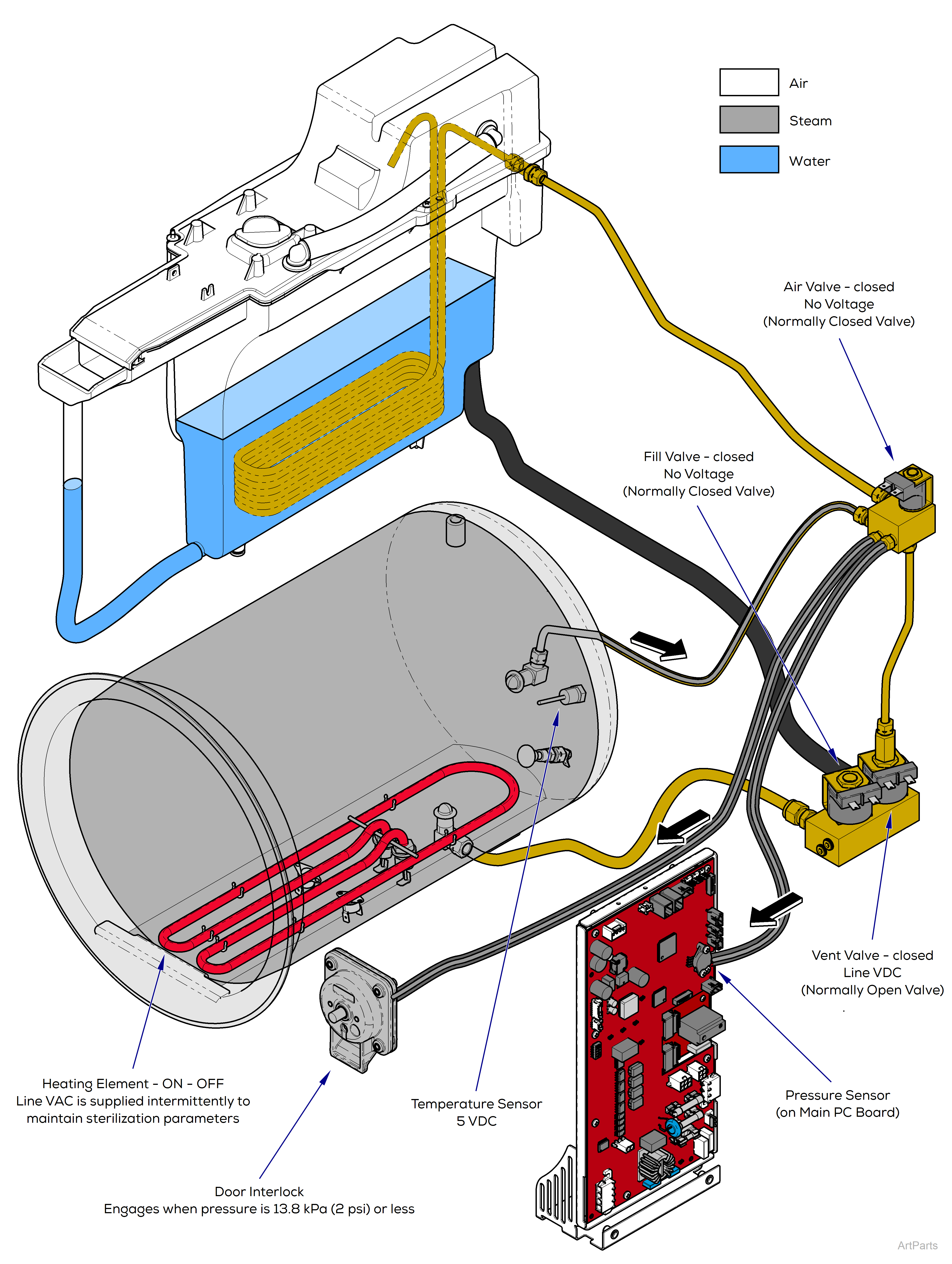

The illustration below calls out the components that affect the Sterilization mode. Refer to the dropdowns for detailed descriptions.

|

Model |

M9 -050, -053 | M11 -050, -051, -053 |

| Serial Number | All | All |

During the Sterilization mode, the temperature and pressure parameters for the selected cycle are maintained for the required time.

The temperature sensor (inside chamber) and pressure sensor (on Main PC Board) monitor the conditions inside the chamber throughout the Sterilization mode.

Based on readings from the temperature sensor and pressure sensor, the heating element is cycled ON/OFF to maintain the required temperature and pressure for the selected cycle.

Throughout the Sterilization mode, voltage is supplied to the (normally open) vent valve. When energized, the vent valve closes. This prevents water from flowing back into the reservoir through the vent valve.

The air valve is closed (no voltage) throughout the entire Sterilization mode. This prevents steam/pressure from escaping the chamber.

During the specialized cycles listed below, the sterilizer follows the standard cycle process. However, the mode will be displayed as follows instead of “Sterilizing”:

•Pre-Heat Cycle

Displays as Holding Temperature (there is no drying phase)

•Monthly Care Cleaning Cycle

Displays as Cleaning (there is no drying phase)

•Monthly Care Rinsing Cycle

Displays as Rinsing (there is no drying phase)