Midmark M9® -05x / M11® -05x Sterilizer Checking for Pressure Leaks Test and Repair

Some procedures require power to be connected with covers removed. Line voltage is present. Use extreme caution to prevent electric shock.

Do not attempt to adjust, modify, or alter in any manner, any part of the pressure vessel. Serious injury and/or damage to the unit may result.

Sterilizer or components may be hot or become hot. Wait until the sterilizer or components are cool to the touch before continuing service.

|

Model |

M9 -050, -053 | M11 -050, -051, -053 |

| Serial Number | All | All |

|

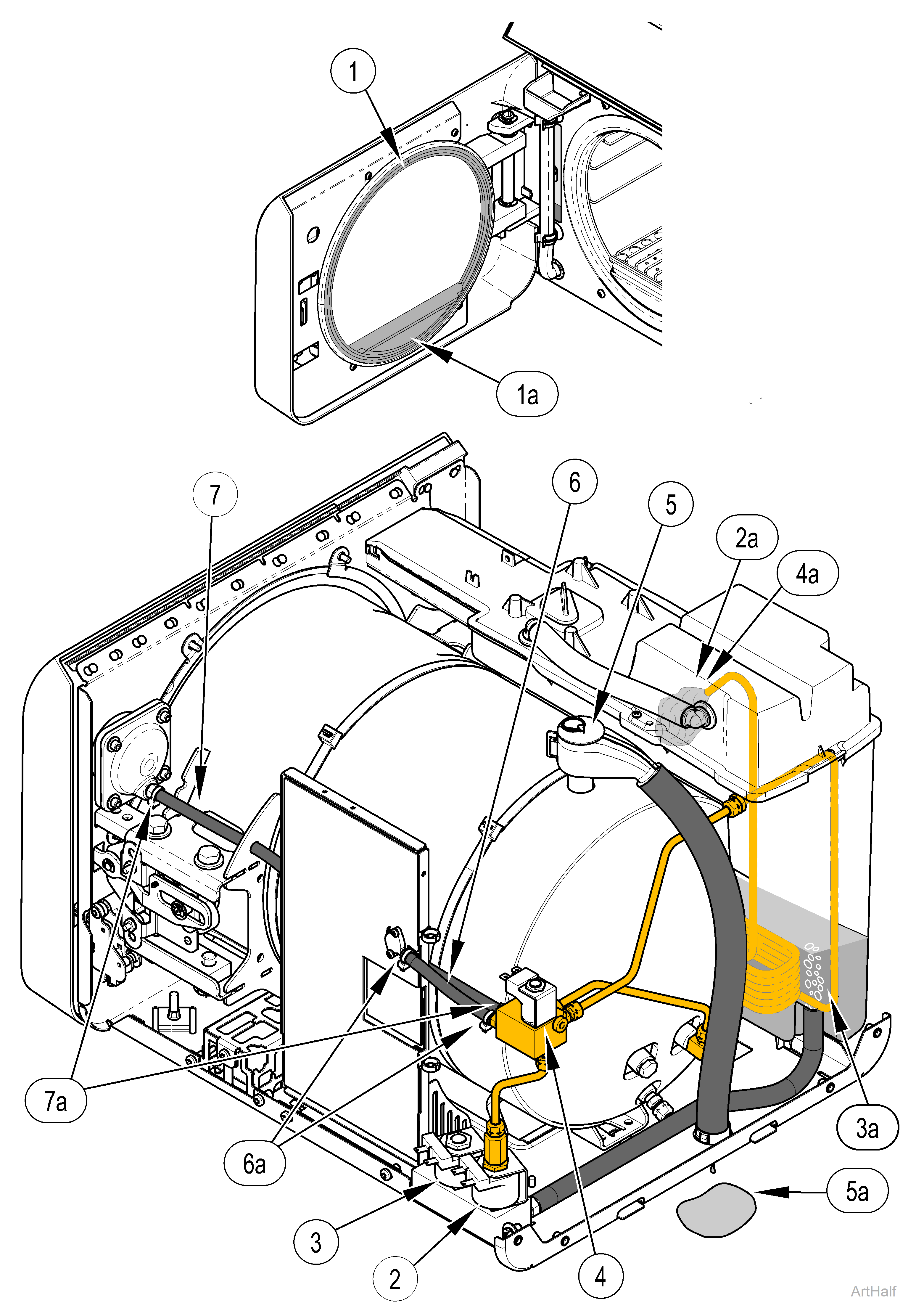

Callout |

Component |

Check |

Correction |

|---|---|---|---|

|

1 |

Door/Dam Gaskets |

Check for water leaking around door (1a). |

Inspect/clean gaskets. Replace gasket(s) if necessary. |

|

2 |

Vent Valve |

Check for water leaking from condensing coil spout (2a). |

Clean/replace vent valve. |

|

3 |

Fill Valve |

Check for water leaking back into reservoir through the fill line (3a). Look for bubbles coming from bottom of reservoir. |

Clean/replace fill valve. |

|

4 |

Air Valve |

Check for excessive steam coming through condensing coil spout (4a). NOTE: During the HEATING and VENTING modes, it is normal for steam to be exhausted through the spout. |

Clean/replace air valve. |

|

5 |

Pressure Relief Valve |

Check for water/steam leakage from beneath the rear of the sterilizer (5a). |

Refer to:Pressure Relief Valve Test. Replace valve if necessary. |

|

6 |

Pressure Sensor Hose |

Check for steam leakage at pressure sensor hose connections (6a). |

Secure pressure sensor hose connection with high temperature cable ties. |

|

7 |

Door Interlock Hose |

Check for steam leakage at door interlock hose connections (7a). |

Secure pressure sensor hose connection with high temperature cable ties. |