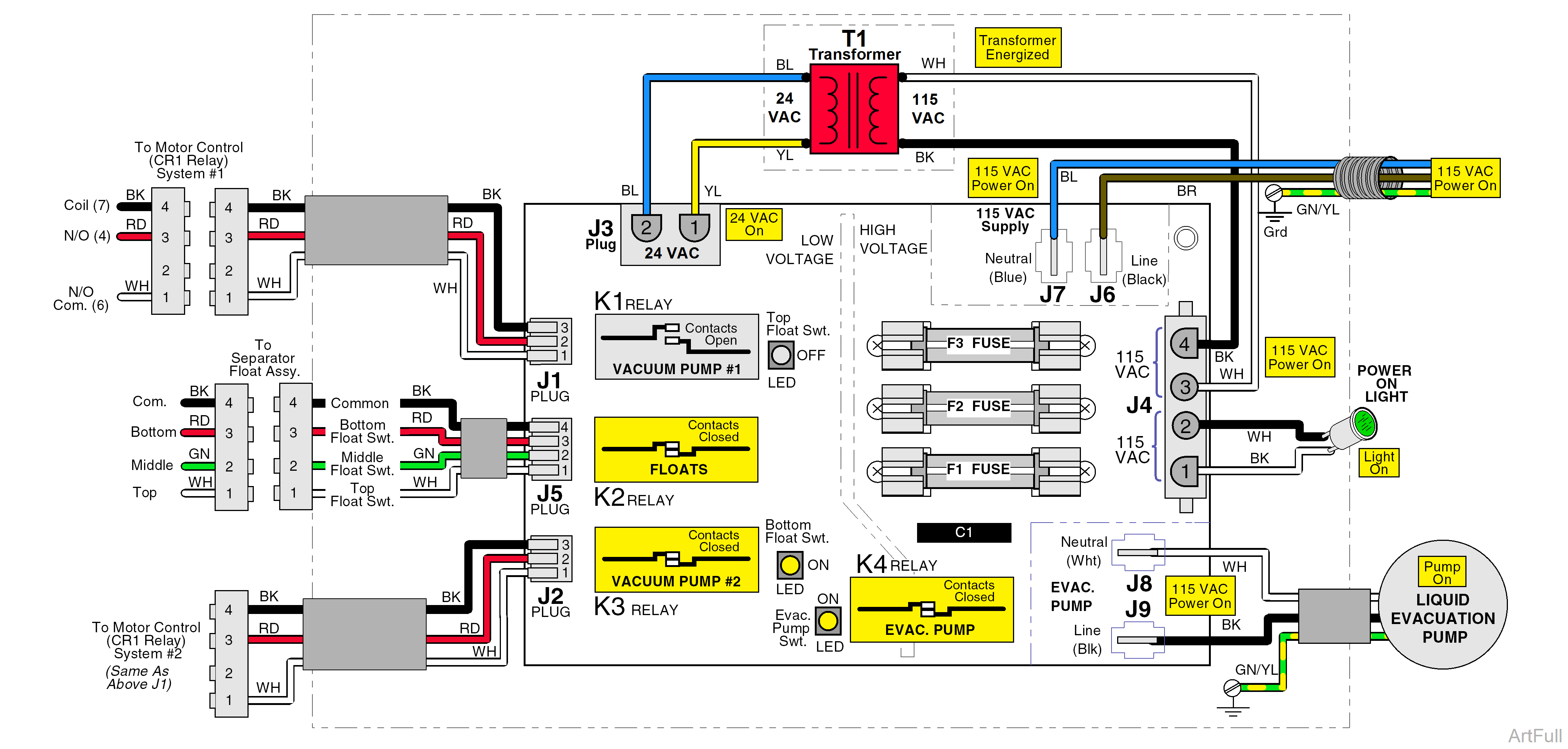

PowerVac® P Electrical System for Liquid Evacuation Pump Troubleshooting

Liquid Evacuation Pump Electrical System shown when the Bottom and Middle Float Switches are Closed and Pump is running. Liquid Evac Pump is Optional. Optional Liquid Evac Pump must use a three float assembly.

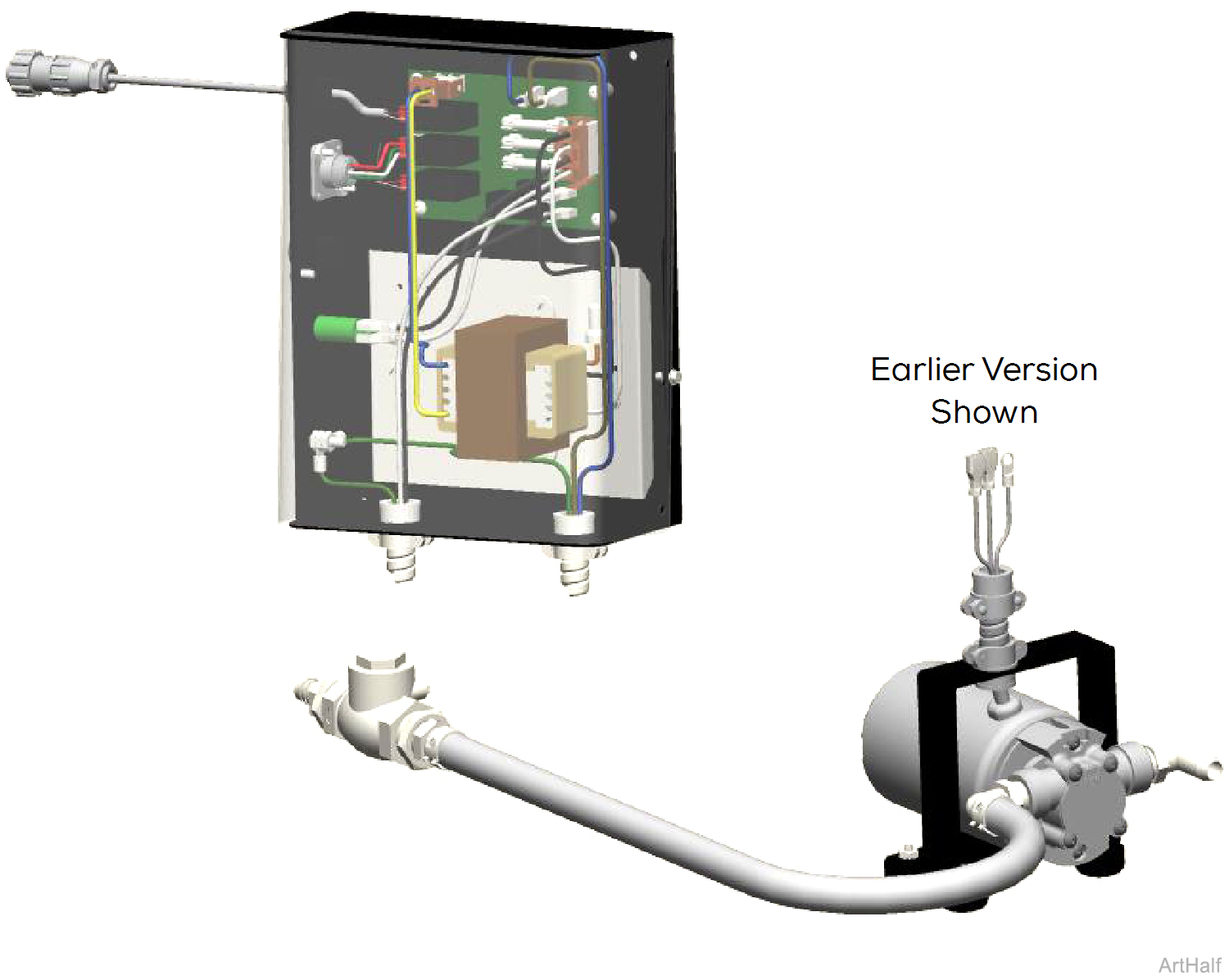

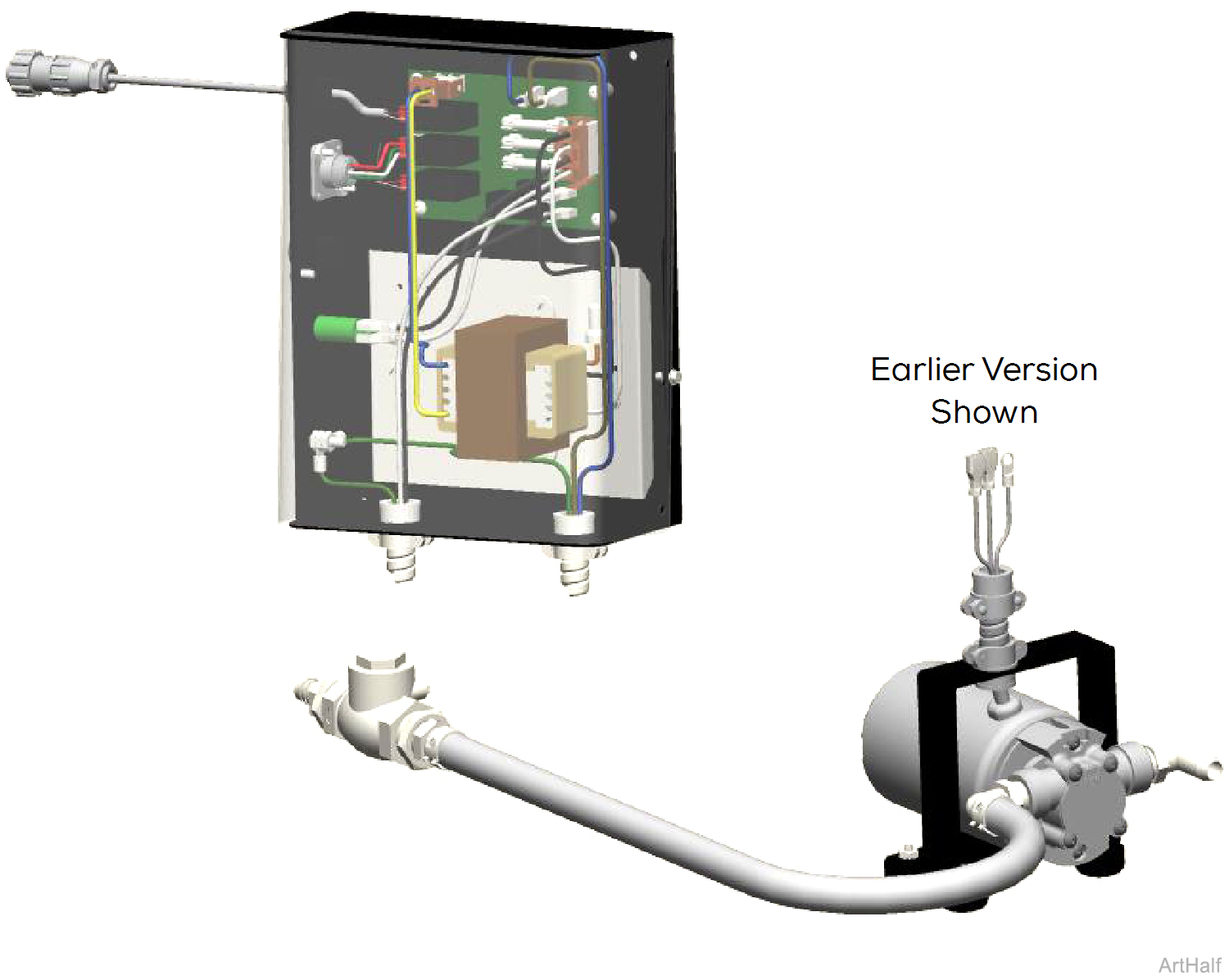

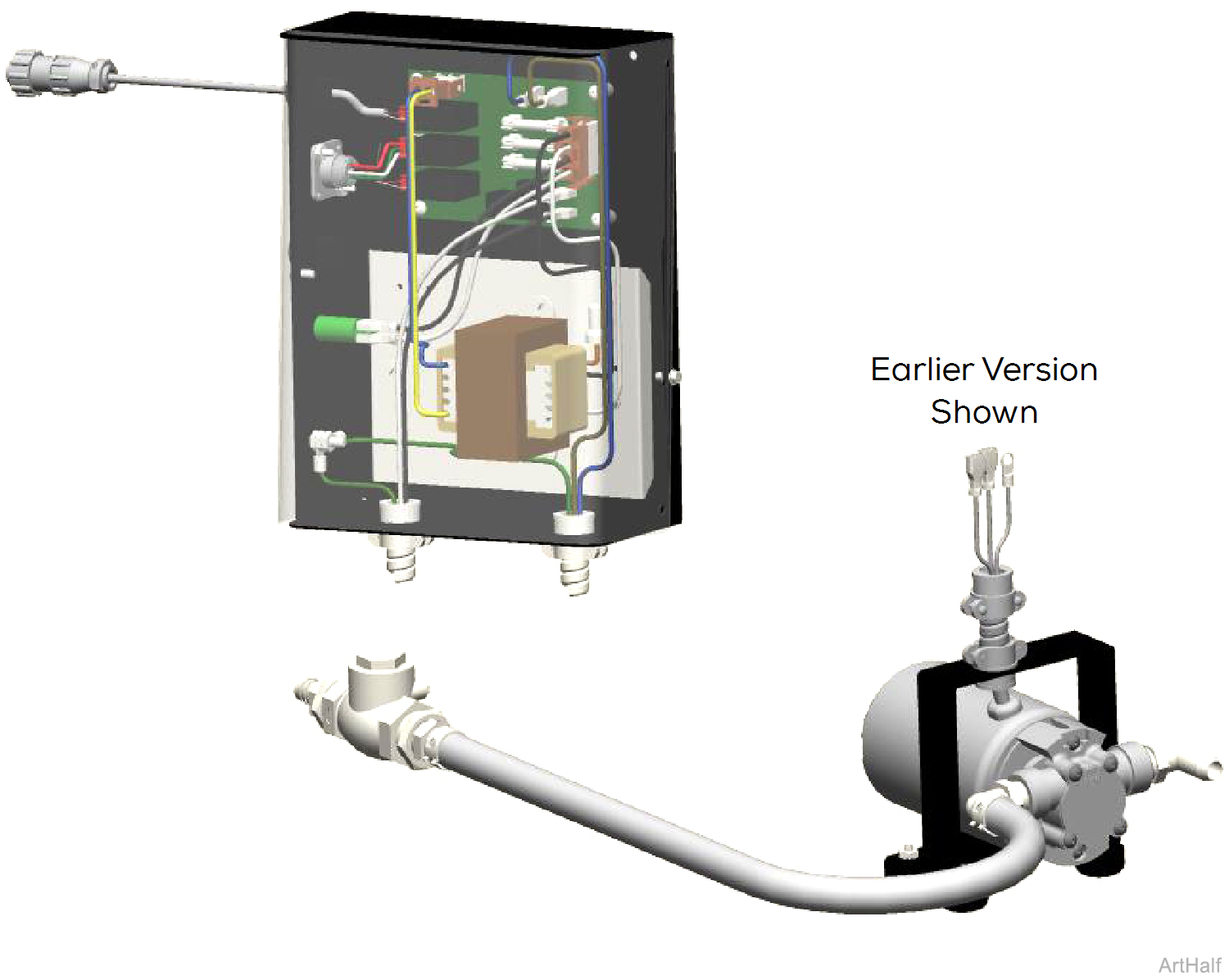

The Liquid Evacuation Pump is an optional accessory for the PowerVac®.

•115 VAC is applied to the 115V / 24V Transformer energizing it.

•24 VAC is applied from one side of the Transformer to the J3 plug.

•When the water level reaches the Bottom float switch, K3 relay contact closes.

•When the water level reaches the Middle float switch, K2 and K4 relay contact close. Power is supplied to J8 and J9 terminals, energizing the Liquid Evacuation Pump.

The Liquid Evacuation Pump will continue to run until the water level drops below the Bottom float switch, opening K3 and K4 relay contacts.

If the Top float closes, K1 relay contacts close, and its LED is on, a problem is occurring with the system. Check for a restriction in the lines, pump not functioning, or PC board problem.

1.Check Supply Voltage to PC Board, Refer to:Liquid Evacuation Pump

2.Check Low Voltage to PC Board, Refer to: Liquid Evacuation Pump

3.Check Float Assembly, Refer to: Float Assembly

4.Check Thermal Motor Protector, Refer to: Liquid Evacuation Pump

5.Check PC Board, Refer to: Liquid Evacuation Pump

6.Check Pump Motor, Refer to: Liquid Evacuation Pump

1.Check Suction Line Into Pump. Check for leaks. Avoid "looping" suction pipe as it could trap air. Suction line should not be more than 6 footin length.

2.Check for Obstructions in Outlet of Separator / Lines. Refer to: Liquid Evacuation Pump

3.Check Evac. Pump Impeller for Obstructions or Damage. Refer to: Liquid Evacuation Pump

4.Check Supply Voltage to Pump. Supply voltage is low. Refer to: Liquid Evacuation Pump

5.Check Pump Location. Pump should be positioned as close as possible below the separator.

6.Check Discharge Line from Pump. Do not run a discharge head of greater then 35 ft. (15 Psi).

1.Check Supply Voltage to Pump. Supply voltage is low. Refer to: Liquid Evacuation Pump

2.Check for Obstructions in Discharge Line from Pump. Refer to: Liquid Evacuation Pump

3.Check Discharge Line from Pump. Do not run a discharge head of greater then 35 ft. (15 Psi).

4.Check Evac. Pump Impeller for Obstructions or Damage. Refer to: Liquid Evacuation Pump

5.Check Pump Location. Pump should be positioned as close as possible below the separator. Suction line should not be more than 6 ft. in length.

6.Check Ambient Temperature at Motor Temperature should not exceed 104° F (40° C) around pump.

7.Motor Thermal Protector Weak. Replace motor pump.