Midmark® Smart Air Compressor Compression Cycle Troubleshooting

Motors start on a 18 second delay.

1.Check Low Voltage. Refer to: Low Voltage

2.Check voltage at Breaker. Was proper voltage is measured at the breaker and not at motor terminals? If yes, check in the following order:

a.Check for broken or loose wires.

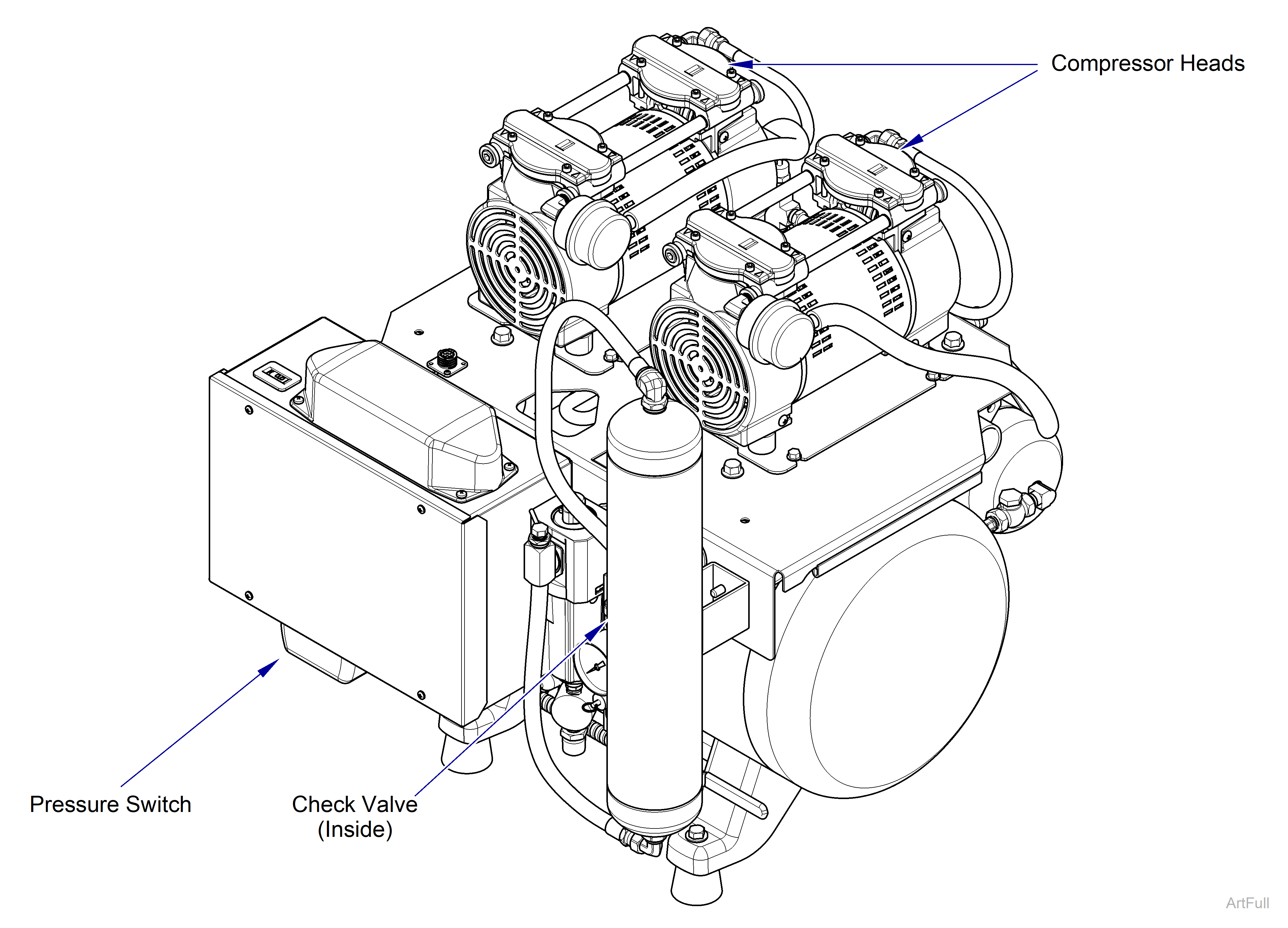

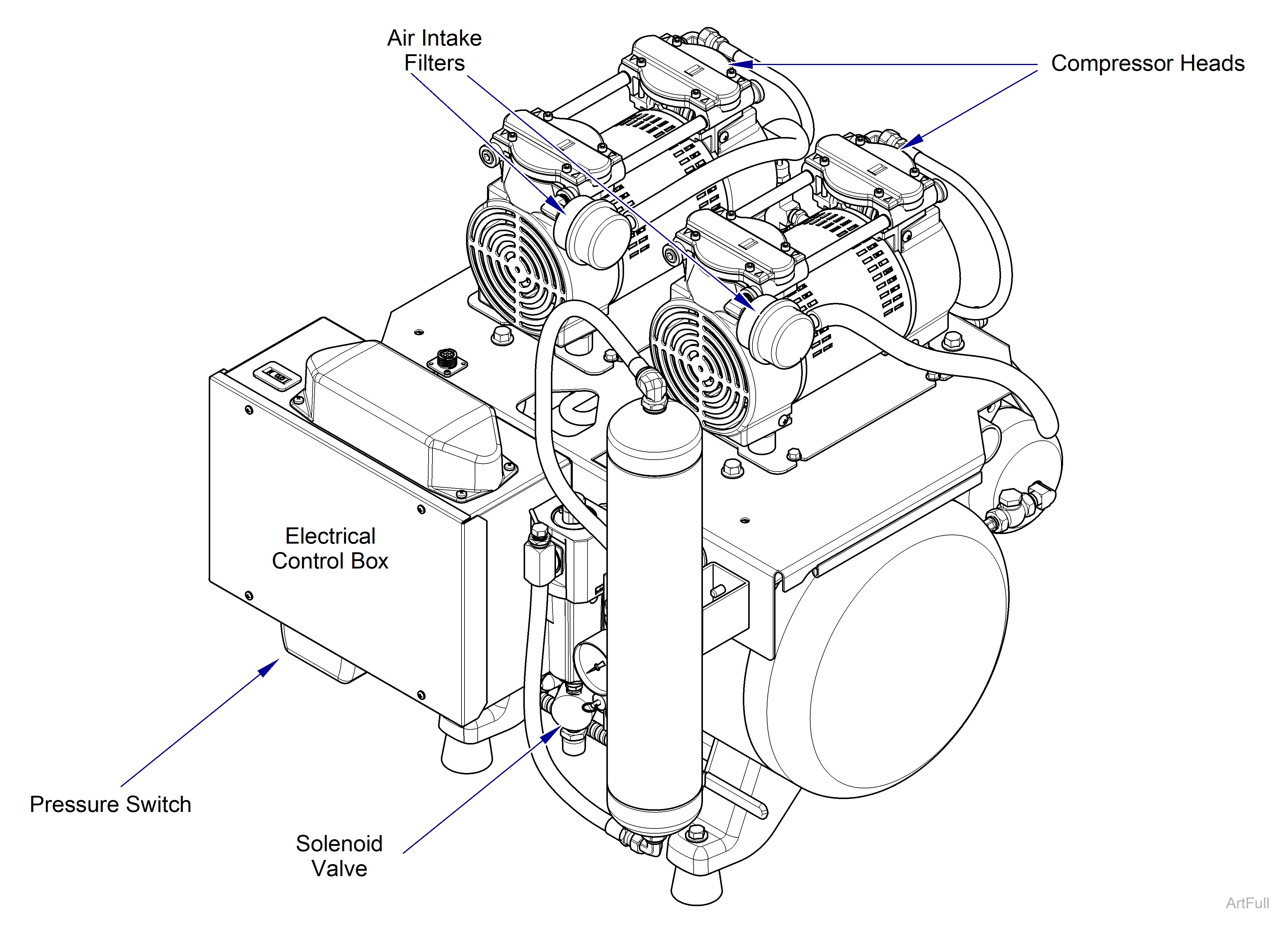

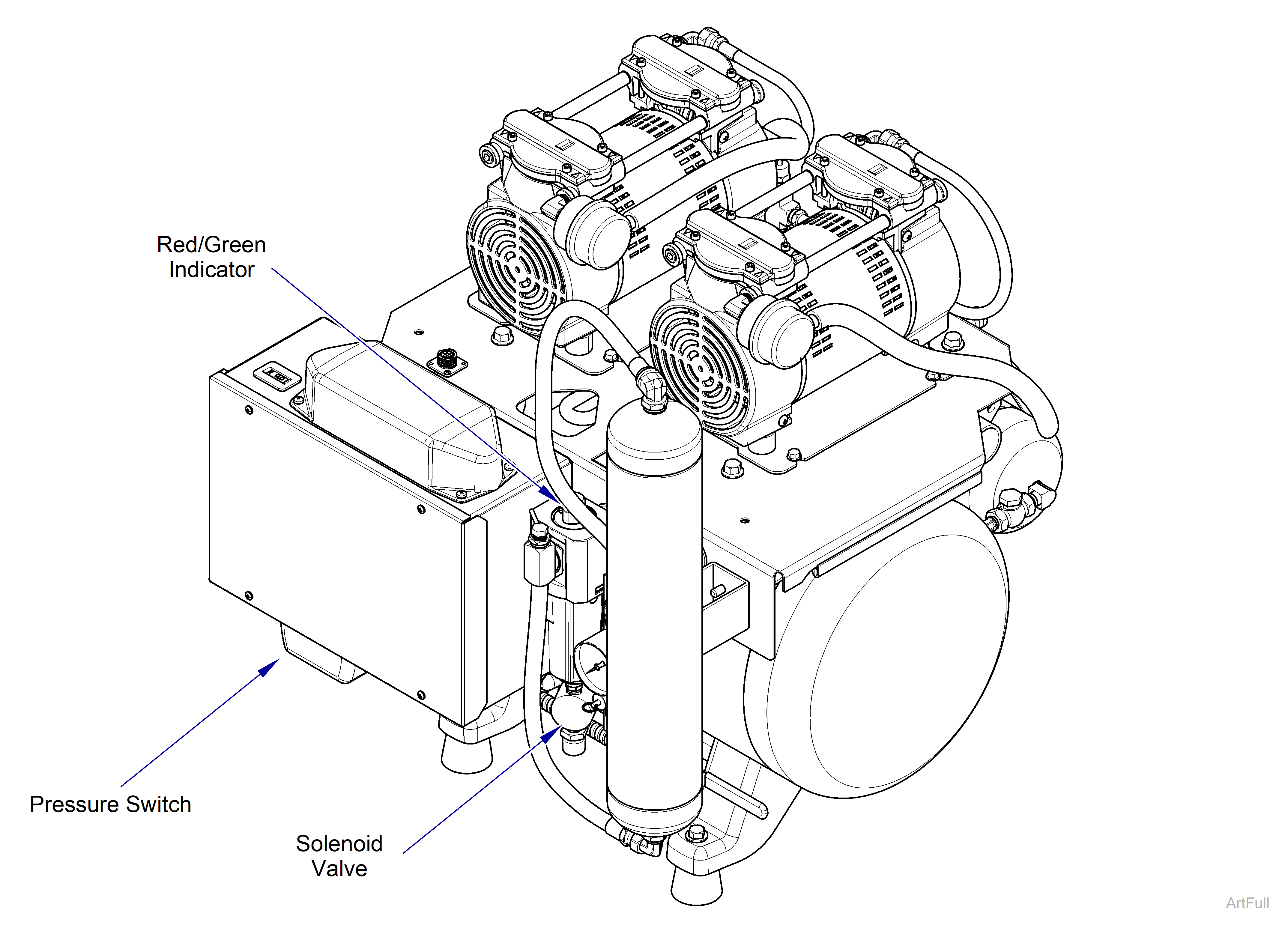

b.If there is Pressure, Perform Pressure Switch Adjustment. Refer to: Pressure Switch

c.Check voltage at On/Off Switch.

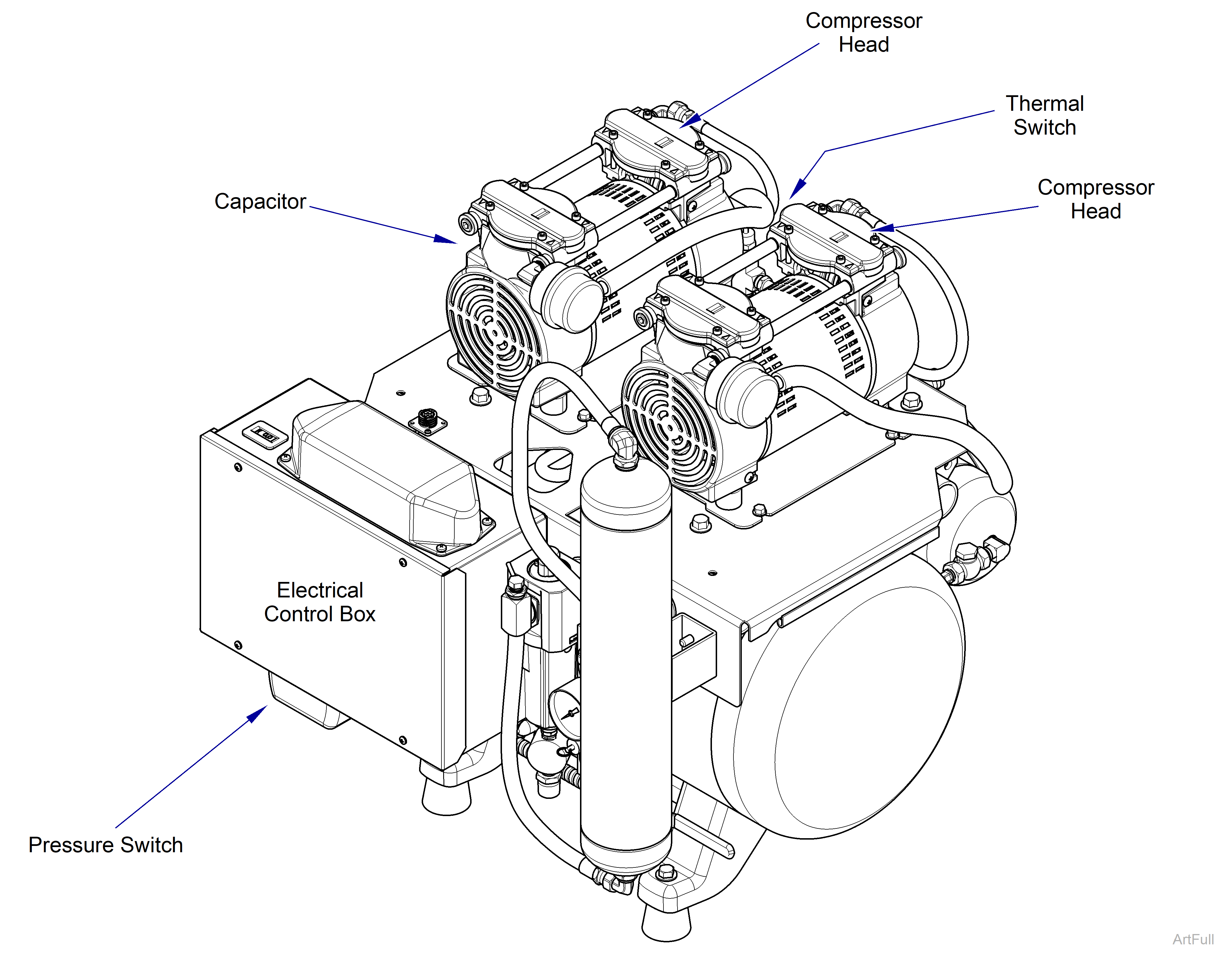

3.Check Capacitor Refer to: Capacitor

4.Thermal Overload Cut. Allow compressor to cool, then restart.

5.Motor/Compressor Frozen. Refer to: Compressor Heads

1.Check Voltage in Breaker.

If circuit breaker is tripped, measure voltage at the line side of the vacuum switch while the unit is running. Voltage should be in the range of 207-253 (for 230 volt units) and 108-132 (for 120 volt units). Voltage outside this range may result in failure to start and possible damage to unit. Install a buck/boost transformer as required.

2.Check Low Voltage. Refer to: Low Voltage

3.Check On/Off Switch.

4.Check Pressure Switch. Refer to: Pressure Switch

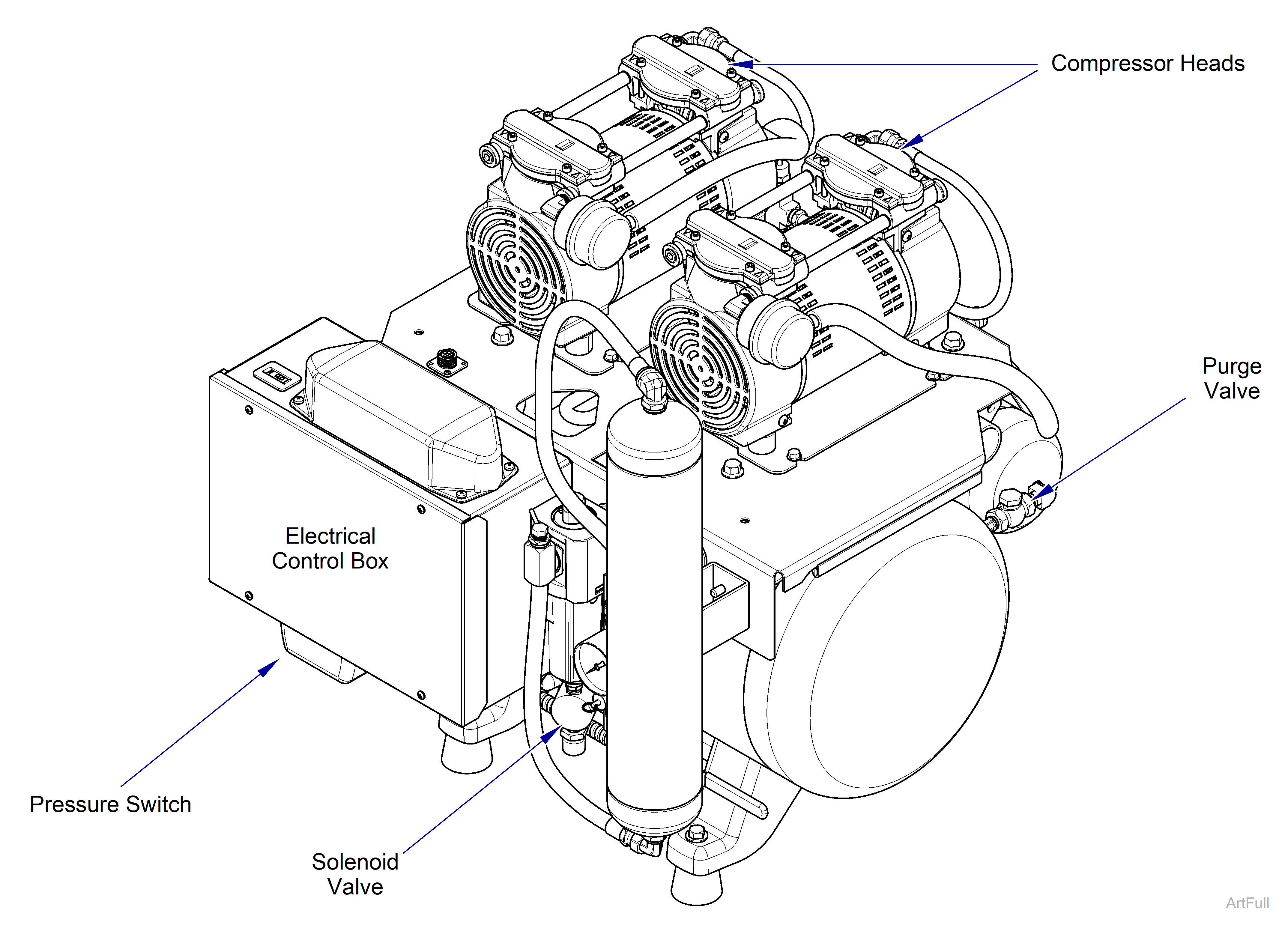

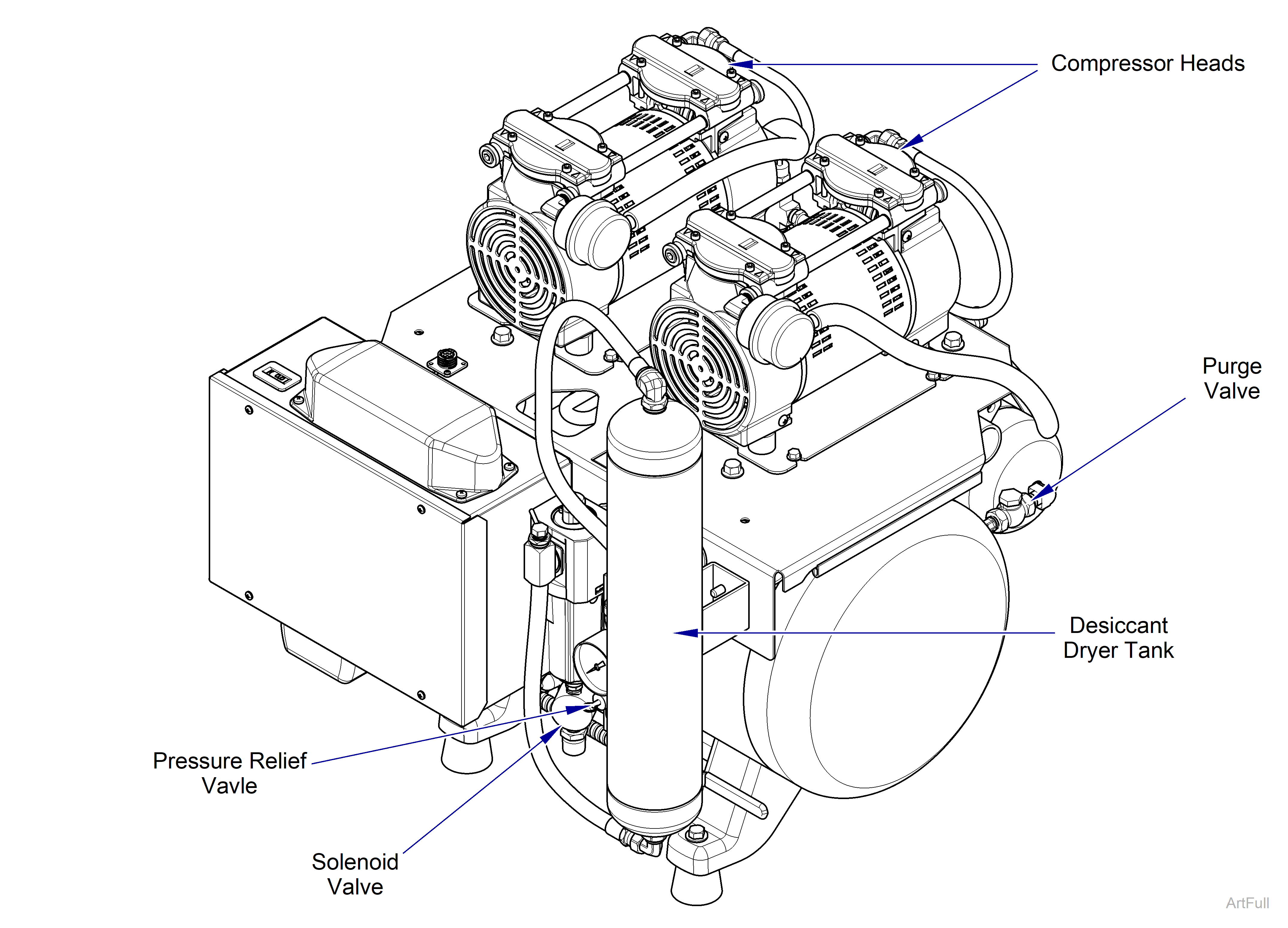

5.Purge System. Purge system by pulling open the pressure relief valve.

6.Check for Blockage in Air Line. Remove discharge hose from head and test run. If unit runs correctly, check for obstruction in air line to storage tank. Obstruction will be at an orifice or other restriction.

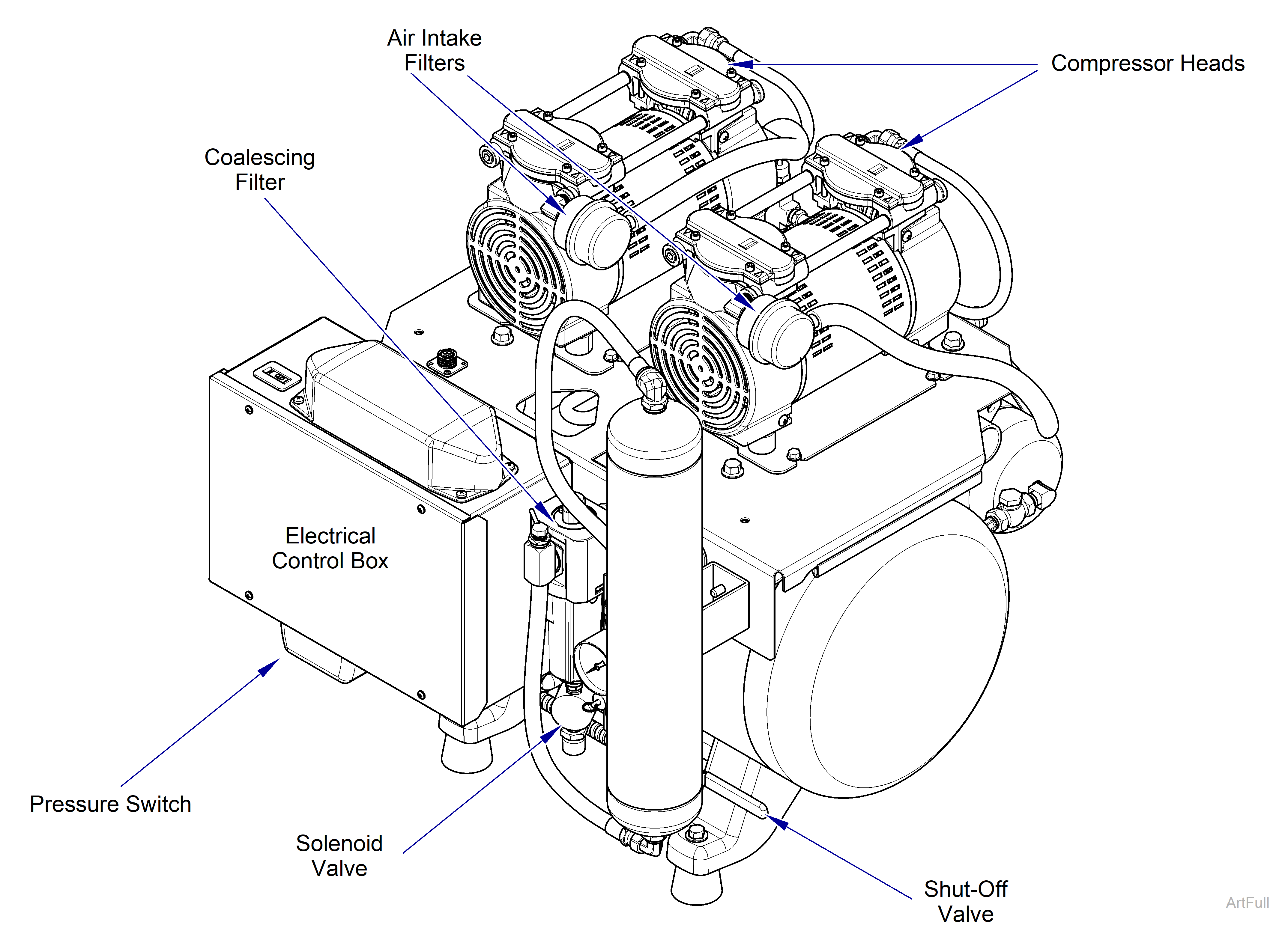

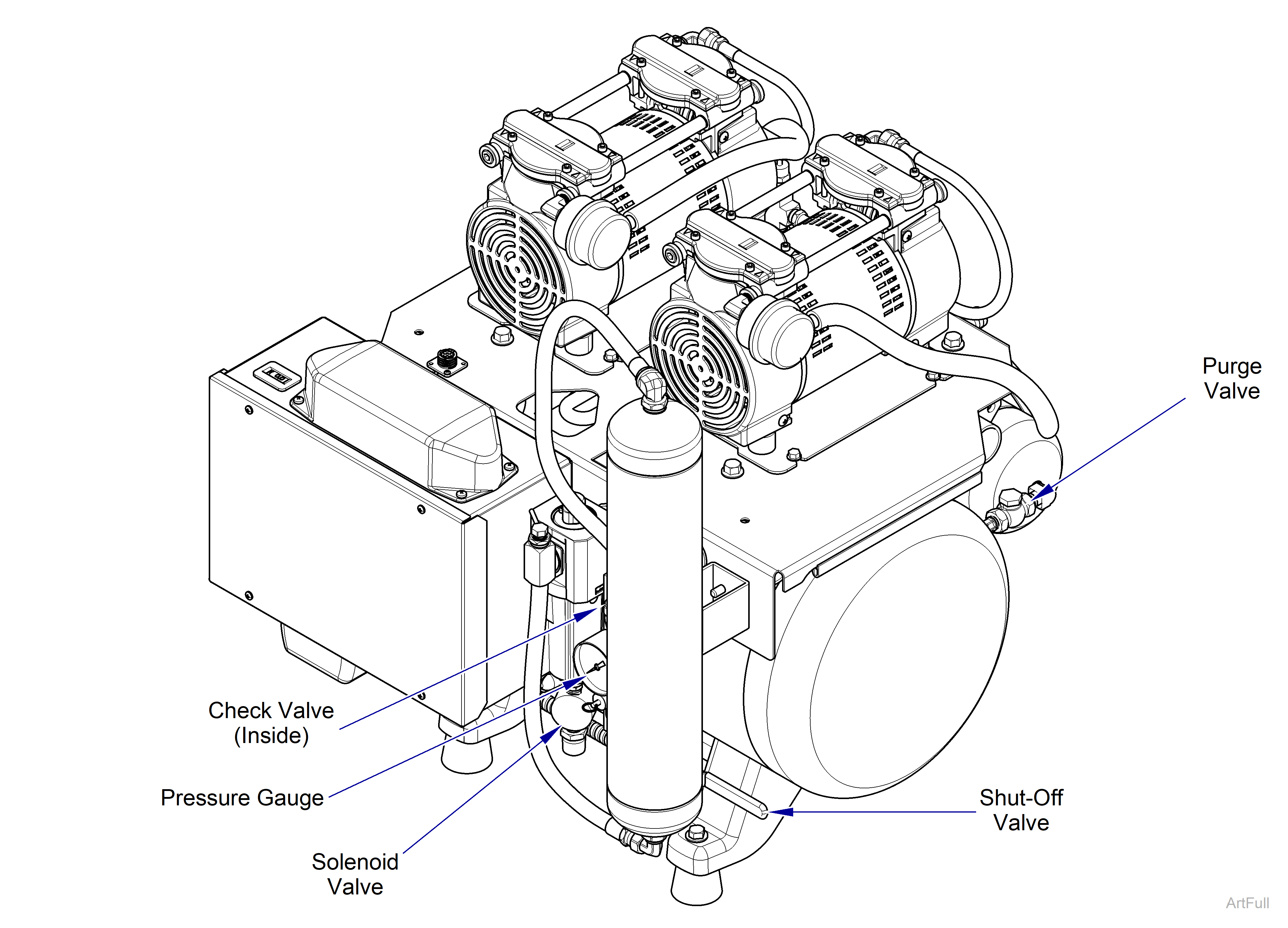

1.Verify Shut-Off valve is Closed.

2.Check Exhaust Valve. Refer to: Solenoid

3.Check Pressure Switch. Refer to: Pressure Switch

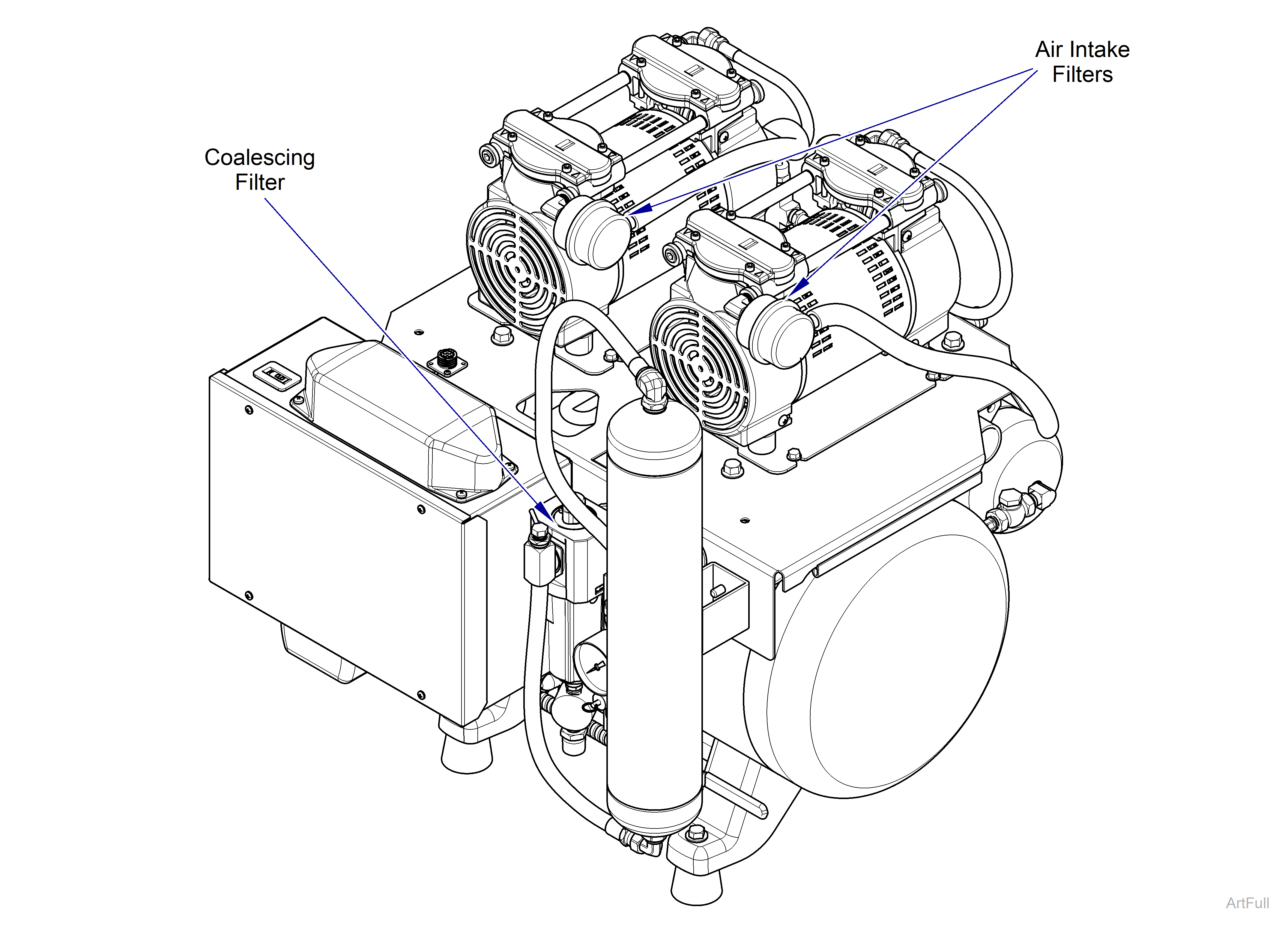

4.Check Coalescing Filter. If indicator is red, change filter. Check for leaks or cracks. Refer to: Coalescing Filter

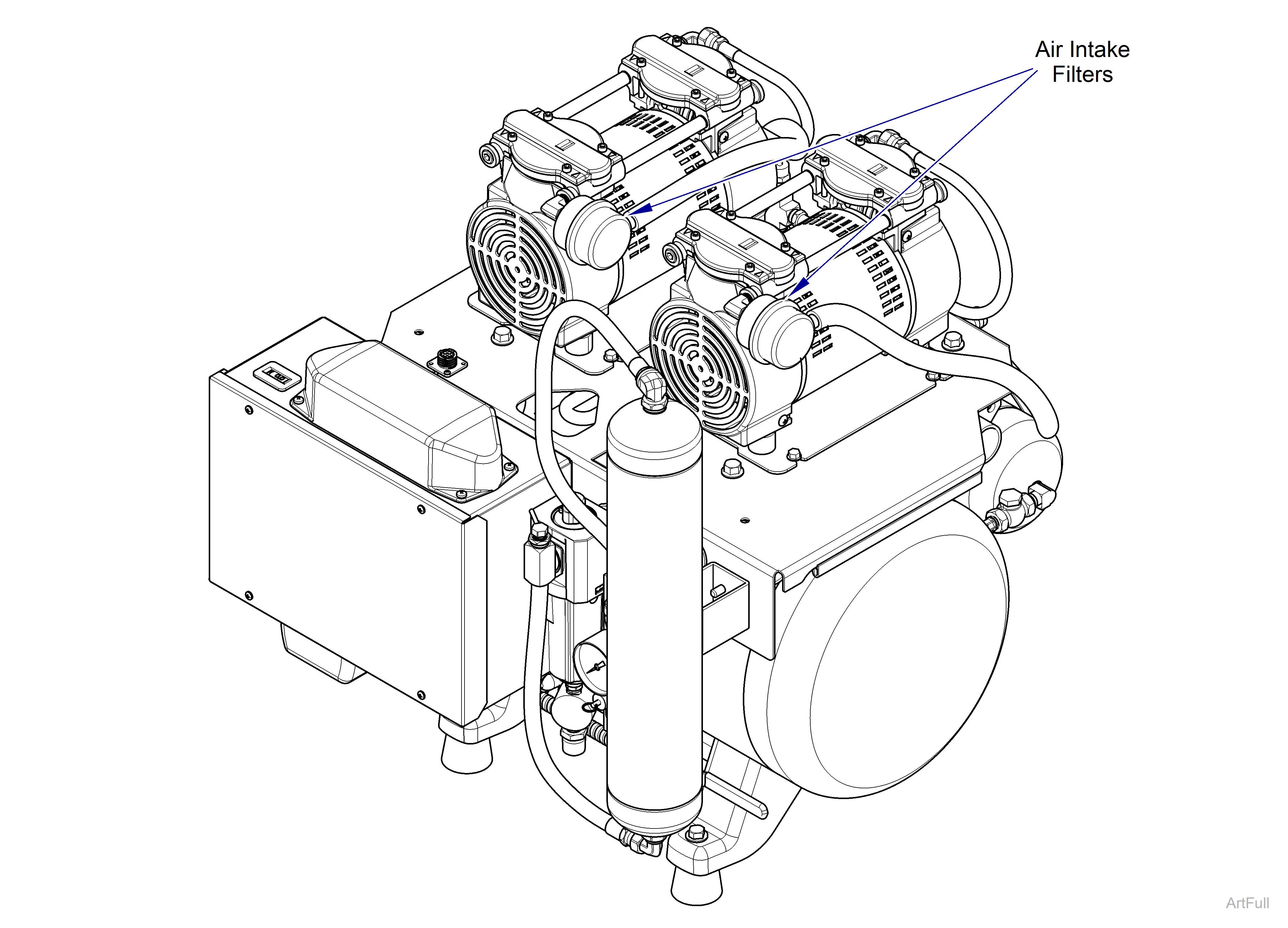

5.Clean or Replace Intake Filter. Refer to: Intake Filter. Intake filters on earlier versions are mounted on a "T" manifold.

6.Check for Blockage in Air Line. Inspect all air lines for restrictions.

7.Check for leaks in Office Air System and in Compressor.

a.Close the storage tank shut off.

b.Pump up storage tank to 100 PSI.

c.If pressure is maintained at 100 PSI for 15-20 minutes, leak is not in compressor. If pressure does not maintain, Refer to: Checking for leaks

8.P21, P22, P32 Models Only, Check for Worn Piston Cup. Refer to: Compressor Heads

1.Check for Leak in Office Air System. Close the storage tank shut off. Pump up storage tank to 100 PSI. If pressure is maintained at 100 PSI for 15-20 minutes, leak is not in compressor

2.Check for Air Leaks. Refer to:Checking for leaks

Under normal operation conditions, a small amount of moisture may be under the unloader exhaust muffler. This is not a malfunction. It is evidence that the filter on the Desiccant Drying System captured the moisture, and did not permit it to enter the operatory air supply.

1.Perform Unloading System Function Test. Refer to:Solenoid

2.Check Desiccant Drying Chamber. Refer to: Desiccant Tank

3.Is Compressor running too frequently? Refer to: "Compressor runs too frequently" section below.

4.Check for Condensation in Air Lines. Is there moisture in operatory air?

5.Purge System. Purge system by pulling open the pressure relief valve.

1.Change Intake Filter. Refer to:Intake Filter

2.Change Coalescing Filter. Refer to: Coalescing Filter

1.Check Exhaust. Remove hoses one at a time between Heads and Pressure Relief Valve. Verify exhaust air flow is not obstructed.

2.Clean or Replace Check Valve. Refer to: Check Valve

3.Check Pressure Switch Settings. Check contacts and operating range, 80 - 100 psi.

1.Check for Leaky Hose. Refer to: Checking for Leaks

2.Replace Intake Filters. Refer to: Intake Filter

3.Oil-Less Compressors with Quiet Cover Only, Check Fans. Refer to: Fans

1.Clean Intake Filters. Refer to: Intake Filter

2.Clean or Replace Exhaust Valve. Refer to: Solenoid

3.Check Exhaust. Remove hoses one at a time between Heads and Pressure Relief Valve. Verify exhaust air flow is not obstructed.

4.Check Voltage in Breaker.

If circuit breaker is tripped, measure voltage at the line side of the vacuum switch while the unit is running. Voltage should be in the range of 207-253 (for 230 volt units) and 108-132 (for 120 volt units). Voltage outside this range may result in failure to start and possible damage to unit. Install a buck/boost transformer as required.

5.Check Low Voltage. Refer to: Low Voltage

6.Check On/Off Switch.

7.Check Pressure Switch. Refer to: Pressure Switch

8.Oil-Less Compressors with Quiet Cover Only, Check Fans. Refer to: Fans

More than the 35% duty cycle for Compressors are rated for would be "Running too Frequently".

1.Check for Air Leaks. Refer to: Checking for leaks

2.Change Element Indicator. Refer to: Coalescing Filter

3.Check Solenoid. Refer to: Solenoid

4.Check Pressure Switch. Refer to: Pressure Switch

1.Do you hear air escaping from the solenoid valve after the compressor shuts off? If yes, check Solenoid. If no, check purge valve for obstruction. Refer to: Purge Valve